ReadSet

Project READSET

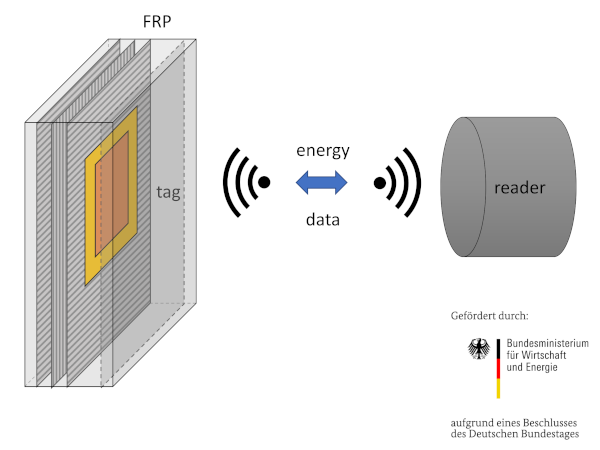

The aim of project READSET (Reproduzierbare Applikation von drahtloser Sensorik in technischen Textilien für Faser-Kunststoff-Verbundbauteile auf Basis passiver RFID-Sensortags‘, i.e. ‘Reproducible application of wireless sensor tags onto technical textiles for fibre reinforced plastics, using passive RFID technology‘) is to develop a wireless, material integrated sensor node (often referred to as ‘sensor tag’) for data acquisition inside a fibre reinforced plastic (FRP) component. Additionally, a system for automatic placement of the sensor node during FRP production is to be developed.

The project is conducted by two institutes: The sensor tag is developed by IMSAS (Institute for Micro systems, Actors, and Sensors) while the system for automatic placement is created by BIBA (Bremer Institut für Produktion und Logistik). The project is funded by the German organization AiF and additionally supported by a variety of companies active in FRP components, sensors and automation technology.

Thematic overview

On one hand, measurement data acquired by the tag during production are intended to be used for process optimization regarding parameters like curing time and curing quality. On the other hand, the tag is supposed to measure mechanical stress during actual product usage in order to gain information about mechanical health of the FRP component in context of a Structural Health Monitoring (SHM).

As of now, commercially available systems for SHM rely on wired sensor components. These wires affect the mechanical integrity of the FRP product, as they pass through the material. Additionally, the moulded-in wires tend to break due to differing elastic modulus of FRP and wire material. Repair or replacement of sensor or wiring is usually either impossible or overly expensive.

Project description

For this reason, the sensor tag to be developed within the scope of the project is to operate wirelessly, so that sensor durability can be improved and the Foreign Body Effect due to sensor integration into the component is reduced simultaneously. In order increase sensor tag service life, the tag is to be supplied with energy exclusively via the magnetic field provided by the associated reader, so that no energy storage has to be incorporated. Existing technologies from the field of RFID (Radio Frequency Identification) technology are a proven and increasingly popular way to implement battery-free systems for energy and data transmission over short distances, so that project READSET uses them for realisation of the sensor tag.

In order to increase economic efficiency of the system and thus enable industrial use, placement of the sensor tags will be carried out completely automatic during FRP production. For this purpose, the BIBA is to develop a handling unit, which is able to apply the sensor tag in a precise position already during layer construction of fibre scrims or fabrics. Communication between tag and handling unit is to take place already during the application process in order to form an intelligent overall system.

IGF Vorhaben Nr.: 20941 N, "Funded by the German federal ministry for economics and energy according to a resolution of the German Bundestag”.

Contact IMSAS

M.Sc. Lukas Bertram

Universität Bremen IMSAS, NW1, Room O2090

Tel.: +49 421 218 62616

E-mail: lbertramprotect me ?!imsas.uni-bremenprotect me ?!.de

M.Sc. Hannes Bender

Universität Bremen IMSAS, NW1, Room N3170

Tel.: +49 421 218 62595

E-mail: hbenderprotect me ?!imsas.uni-bremenprotect me ?!.de

Prof. Dr.-Ing. WalterLang

IMSAS, NW1, Room O2120

Tel.: +49 421 218 62602

E-Mail: wlangprotect me ?!imsas.uni-bremenprotect me ?!.de

Contact BIBA

M.Sc. Michael Brink

Universität Bremen Universität Bremen

Tel.: +49 421 218 64873

E-mail: briprotect me ?!biba.uni-bremenprotect me ?!.de