Nicole Wielki, Heike Sonnenberg, Daniel Meyer, Brigitte Clausen

Journal of Materials Processing Technology (2021) 289, 116960.

https://doi.org/10.1016/j.jmatprotec.2020.116960

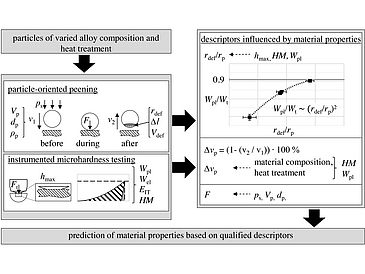

The material and its microstructure define the behaviour of a part in a deformation process. A single particle deformation process is introduced as a rapid material characterization method extending already existing approaches. Particle-oriented peening is performed with spherical micro samples of the low carbon steel 100Cr6 (AISI 52100) and the martensitic stainless steel X46Cr13 (AISI 420). Three different diameters (0.6 mm, 0.8 mm and 1.0 mm) were chosen to investigate the impact of the material and the surface to volume ratio. By processing single particles, the mechanical and geometrical properties of the particle before and after the impact can be linked to the deformation behaviour during the peening process. The elastic and plastic material properties are revealed by studying the remaining plastic deformation of the particle and the velocity reduction as a result of the impact. Instrumented universal micro hardness measurements are carried out to determine the hardness of the particles and to correlate it with the behavior of the particles during the particle-oriented peening process. The plastic deformation work as a characteristic value of micro hardness measurements of the different material states is discussed. It is conceivable that the consideration of different material behaviour related values (so-called descriptors) may replace conventional material testing in the future. Using short-term characterization methods like the particle-oriented peening a fast determination of material properties is possible.

© 2020 Elsevier B.V., https://doi.org/10.1016/j.asr.2020.09.026