The University of Bremen is the very first university in Germany to possess a laboratory for testing large gear wheels. The Bremen Institute for Metrology, Automation and Quality Science (BIMAQ) recently commissioned a special large coordinate measuring device and has subsequently opened the “Laboratory for Measuring Large Gear Wheels”.

The researchers at BIMAQ think in terms of micrometers. You would be forgiven, then, for not knowing that they need a license to drive a fork-lift truck in order to carry out their work. Somehow, though, the huge gear wheels weighing several tons – such as those used in large wind turbines – have to be transported and placed onto the measuring table of the coordinate measuring equipment. Therefore, over the past two years it has taken to construct the large building that houses the laboratory they had to learn how to drive a forklift. In the meanwhile they have become expert at moving the sensitive and unhandy colossuses around and putting them down gently on the precise point where they are required.

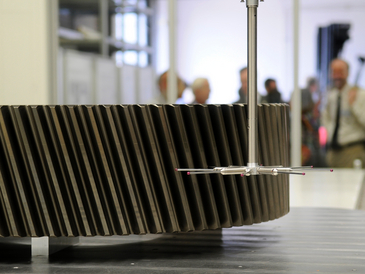

Now, using a specially designed Leitz-coordinator device made by Hexagon Metrology (Wetzlar), the Bremen researchers can carry out high-precision tests on gear wheels with diameters of up to three meters in an air-conditioned chamber that ensures a constant temperature. August 2009 saw the start of a project funded by the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) in an amount of € 1 million: the project will be completed when the special equipment worth some € 730,000 becomes operational. “Now we can begin our research work”, says BIMAQ leader Prof. Dr.-Ing. Gert Goch.

The highest precision is called for to ensure smooth operation – even in the case of especially large gear wheels. “Quality tests are crucial for the production of the gear wheels and their ultimate use”, Goch explains. “Among other things, our research is expected to bring about a decisive improvement in the reliability of large-scale gear applications in wind power turbines. They are subjected to extreme stresses and their production calls for quite different specifications than the large gear wheels found in ships or power stations, for instance.” Damage to the bearings and gear wheels of wind power turbines would lead to disproportionately high costs – especially offshore.

More information under www.bimaq.de