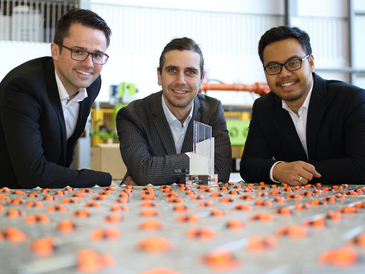

A team of three researchers from the Bremen Institute for Production and Logistics (BIBA) at the University of Bremen recently seized the opportunity to present their novel conveyor system called “Celluveyor” to a large international audience during “DHL Innovation Day”. They were one of only three teams eventually selected to compete in the final round of “Shark Tank”, a competition that enables new entrepreneurs and start-ups to present their ideas to potential investors. The small jury of high-caliber experts bestowed the first prize on the Bremen team. The “Celluveyor” will now be put on show in the DHL Innovation Center’s start-up hall of fame in Troisdorf.

Wanted: Innovative ideas and promising start-ups in the logistics sector

In the frame of Shark Tank, DHL seeks “innovative ideas and top young entrepreneurs in the logistics sector”. The candidates initially competed against each other during a so-called start-up pitch. Then, within a very short period of time, they had to convincingly present their new product and a business model. The verdict of the public and the expert jury – comprising Dr. Alex von Frankenberg from High-Tech Gründerfonds, Peer Bentzen from DHL and investor Frank Thelen, known to many from the Shark Tank TV series “The Dragon’s Den” – fell on the Celluveyor team from Bremen.

An elementary component for the digital factory of tomorrow

BIBA researcher Claudio Uriarte, who thought up the idea, called the conveyor system “Cellular Conveyor”, or “Celluveyor” for short. “Cellular” because its structure is made up of cells and “Conveyor” is English for the German word “Förderband”, which means “conveyor belt” – though this innovative omnidirectional and multi-functional piece of equipment has precious little in common with a conventional conveyor belt.

Celluveyor is an extremely flexible modular conveying and positioning system based on the concept of cellular intralogistics. Small hexagonal modules are fitted with specially arranged omnidirectional wheels that can be precision-driven separately from one another. In this way it is possible to transport and position several objects simultaneously and separately on individually programmed tracks. In this way, the Celluveyor can carry out complex materials-flow tasks within the smallest of places.

Owing to its simple construction, the system can be easily and flexibly adapted to fit specific requirements, opening up virtually endless possibilities. Moreover, it is very lightweight, cost-efficient, and easy to maintain. Its intelligent drive system could well make it an elementary component of the digital factory of tomorrow.

A university spin-off enterprise with support from the EXIST program

“Winning this competition is great additional motivation for us”, says BIBA researcher Dr.-Ing. Hendrik Thamer. Together with Uriarte and Ariandy Yoga Benggolo, another BIBA colleague, he is preparing the business start-up planned for early 2017. The aspiring entrepreneur will receive support from the EXIST research transfer program funded by the Federal Ministry for the Economy.

Results of research simply left to gather dust in the laboratory

“We’re not content to leave it just as a good idea with a functioning demonstrator. The challenge now is to develop a viable business model, refine the concept, and take it to market”, says BIBA director, Professor Michael Freitag. “After all, what would be the point of brilliant ideas and developments if the results of research were simply left to gather dust in the laboratory?” he asks, and criticizes that this is all too often the case.

“We want to do it differently. Research and development should lead to application in the practice”, says Freitag. With this in mind, BIBA cooperates closely with “InnoWi”, a Bremen patent and valorization agency. Together with InnoWi, BIBA organizes regular information events for its researchers, among others on the topics of patenting procedures and marketing. The institute also calls in engineering and marketing experts in the early stages of research projects closely related to practical applications.

“Industry 4.0 needs solutions like this in the area of technical logistics”

For example, innovation manager Ernesto Morales Kluge from InnoWi has been accompanying the Celluveyor project for a good four years now. He has been in close contact with the start-up team ever since the idea first reached maturity, among other things conducting market and cost-benefit analyses. He also helped draw up plans for the further development and valorization of Celluveyor and worked with the team on submitting applications for funding. And he prepared BIBA’s application for a European patent – a tedious and time-consuming process.

Morales Kluge is happy the way the project is turning out. “This kind of success also shows that the innovation manager is doing a good job.” It took extensive research and analysis before InnoWi recommended BIBA should invest in research on the Celluveyor as well as the subsequent patenting procedure, presences at trade fairs, and presentations. Morales Kluge has absolutely no doubt that “Industry 4.0 needs solutions like this in the area of technical logistics“.

If you would like to have more information, feel free to contact:

Prof.Dr.-Ing. Michael Freitag

phone: +49 421 218-50 002

email: freprotect me ?!biba.uni-bremenprotect me ?!.de

Dr.-Ing. Hendrik Thamer

phone: +49 421 218-50 160

email: thaprotect me ?!biba.uni-bremenprotect me ?!.de

Dipl.-Wi.-Ing. Ernesto Morales Kluge

phone: +49 421 96007 19

email: ernesto.moralesprotect me ?!innowiprotect me ?!.de