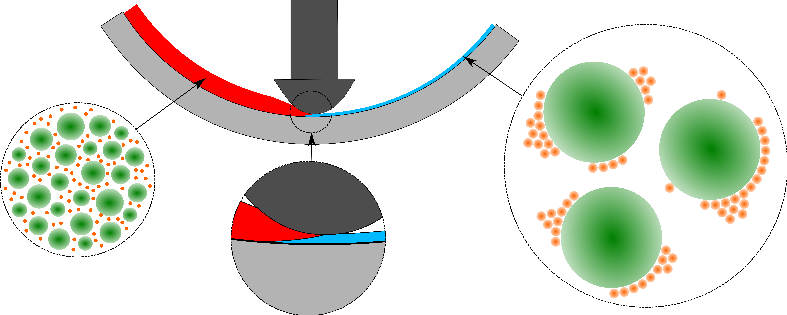

Agglomeration applying high intensity mixing (mechano-fusion)

An integrated approach towards the synthesis of tailored heteroaggregates combining experiments with 2D and 3D structural characterization via image analysis and stochastic modeling

Project Leader :

Prof. Dr.-Ing. Urs Peuker

TU Bergakademie Freiberg

Prof. Dr. Volker Schmidt

University of Ulm

The special properties of hetero-aggregates derive from the particle-particle contacts within the aggregate. The number of contacts as well as microscopic material interaction at the contacts play a decisive role regarding macroscopic application properties. Examples are transport properties like electric, ionic or thermal conductivity. The first funding period investigates the mixing and therefore the geometric 3D structure of the aggregates.

The project applies the mechano-fusion process, which is situated between grinding and high intensity mixing processes, to generate hetero-aggregates from primary nano-particle systems. The aggregate synthesis occurs due to a dynamic de-agglomeration and re-agglomeration process, where the high shear and yield stresses in the machine lead to stable particle-particle contacts in the aggregate. The process is able to generate both core particles with a hetero - aggregate coating and bulk hetero - aggregates . The investigations willquantify the disperse and material properties of the primary particles , which are required for a defined aggregate design .

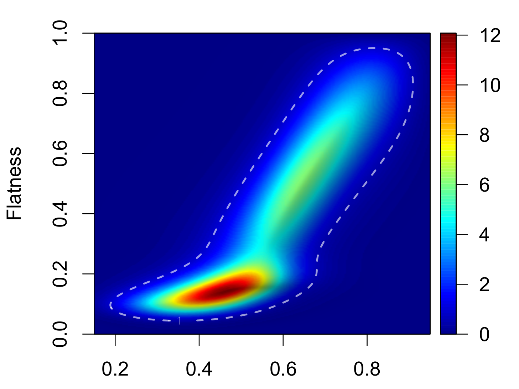

The hetero-aggregates are submitted to 2D- and 3D-characterization methods to quantify the state of mixing of the primary particles within the individual aggregate structures. Image analysis of nano- and μ-computer tomography (CT) data provides detailed 3D-insight into the aggregates. The analysis uses methods of statistical data mining to determine the

multivariate probability distribution of structural descriptor vectors of hetero- aggregates, and spatial stochastic modeling to create virtual (but realistic) aggregates, i.e. simulated aggregates, to generate a large data base to apply machine learning algorithms. Correlative characterization methods, e.g. the combination of atomic force microscopy at 2D with μ-CT, allow to

cross check whether it is also feasible to forecast 3D structural aggregate properties from planar, i.e. 2D measurements of the mixing state.

The second funding period will also have a look at the atomic level, especially at the hetero-contacts, where different materials interact with each other. The intensive shear und yield stressing in the mechano-fusion process is able to tailor the material welding at these contact points generating or enhancing macroscopic properties. Finally, quantitative process-structure-property relationships will be derived, correlating process parameters with the 3D morphology of real and simulated hetero-aggregates

and their macroscopic physical properties.