Ion and electron conducting hetero-aggregates for electrochemical applications

Project Leader :

Prof. Dr. Jürgen Janek

Justus Liebig University Giessen

Prof. Dr.-Ing. Arno Kwade

Technical University of Braunschweig

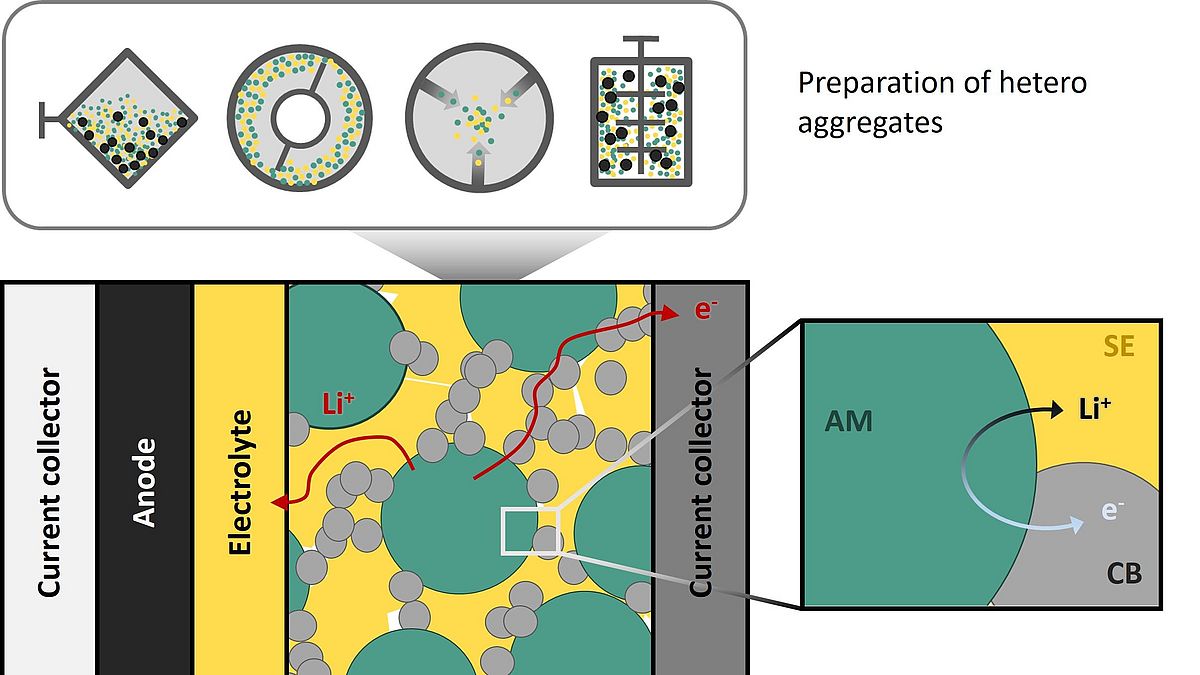

A new generation of Lithium-batteries, the so-called all solid state batteries (ASSB), with solid electrolytes (SE) replacing the liquid ones is recently under development to potentially increase energy density and safety. However, the submicron structure within the cathodes, i.e. local distributions of active material, solid electrolyte as well as conductive additive particles and most probably a binder, is very decisive for the electron and ion transport as well as for the possible mechanical degradation of the cathode and, thus, the resulting battery cell performance. Our hypothesis from the materials perspective is that smaller particle sizes ≤ 1 µm of active material and solid electrolyte of are advantageous, once these particles are homogeneously mixed and result in a tailored particulate structure.

However, the exact effect of the submicron structure on the cell performance is hardly known. Moreover, processes to produce these solid state cathodes are not well investigated, yet. Additionally, with regard to the minimization of the CO2-footprint and production costs, the cathodes for the upcoming all solid state batteries should be produced by dry processes, which requires an efficient and well understood mixing process for the different solid components and, thus, the development of targeted structuring of hetero agglomerates/aggregates (in the following named as aggregates). We will investigate four different processes providing different modes, intensities and frequencies of stresses and evaluate the effect of the stress conditions on the aggregate morphology and structure characteristics, measured among others by FIB-SEM.

The stress conditions will be determined based on appropriate DEM-simulations. Our hypothesis from this perspective is that if the stress history acting on the particulate materials is known, the structure of the hetero aggregates and on this basis their performance properties – especially their electronic and ionic conductivities – shall be predictable. In order to deeply understand the effect of the hetero aggregate structure on the physico- and electro-chemical properties, the heterointerfaces in the aggregates will be probed by SIMS and KPFM with respect to eventual decomposition products and the potential drop across these interfaces. 3D tomography (HR-SEM and SIMS) will be carried out and in combination with in-situ 3-electrode electrochemical analysis in the SEM, ionic and electrical percolation will be studied as function of aggregate structure.

The mechanical and conductivity properties of selected aggregate structures will also be simulated using DEM in order to be able to predict the properties in the future. Our hypothesis from the analytical perspective is that the feedback loop between particle processing and systematic analytical characterization on the nm and µm scale will lead to optimized particle aggregates and resulting cathode composites.