Realization and analysis of jet-based direct mixing gas phase aggregation for the formation of hetero-aggregates with new properties

Project Leader :

Prof. Dr.-Ing. Harald Kruggel-Emden

Berlin Institute of Technology

Prof. Dr.-Ing. habil. Eberhard Schmidt

University of Wuppertal

Overall aim of the proposed research work is to contribute to the development of new particulate products based on hetero-aggregates being formed in the gas phase. To reach this goal it is first required to establish gas phase-based processes which allow the controlled formation of heteroaggregates in sufficient quantity and quality. As these processes are clearly still lacking, a jet-based process is proposed, realized and simulated as part of the first funding period of SPP 2289 applied for here by the groups of Kruggel-Emden at Technische Universität Berlin and Schmidt at Bergische Universität Wuppertal.

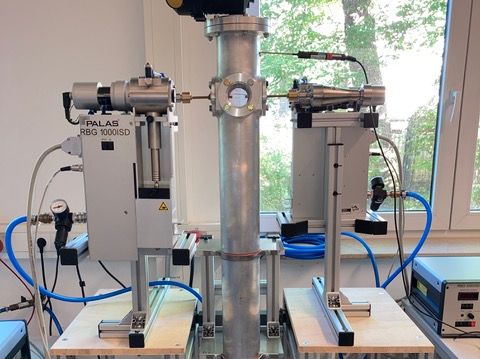

The jet-based process consists of three steps. In a first step the different primary particles are isolated as part of a carrier gas stream after a possible disaggregation has taken place if required. In a second step the jets with the different primary particles interact with each other allowing for the contact of the different primary particles enabling the formation of hetero-aggregates. In a third step the formed hetero-aggregates need to be removed from the jet interaction zone in a controlled way. Note that thermal stabilization is not considered as part of the first funding period here. Currently the process parameters of the outlined process as well as the three subprocesses are unknown with respect to optimizing throughput and quality of the formed hetero-aggregates.

The latter overall process including the three subprocesses should be therefore investigated which requires a process analysis which can be performed based on an analysis of the aggregates formed done off-line by sampling, however methods to get spatially resolved insights into the process by laser diffraction and flow analysis should be also explored to understand about the relevant subprocesses. Additionally, the structure of the formed hetero-aggregates should be evaluated by off-line performed imaging techniques (SEM, EDX) to link structure with single aggregate properties.

Furthermore, as the timeand length-scales are small and therefore challenging, the gas phase-based process is recreated as part of a DEM/CFD. After an appropriate model calibration and model validation which is achieved by in detail benchmarking with the experimental investigations, it is thereby aimed for to learn about process details which are not accessible experimentally as part of funding period one.

Thereby, the modelling aims for providing all necessary ingredients to perform ab-initio process design in the future which is essential to contribute to the overall aim of developing new particulate products based on hetero-aggregates in the future. The bulk behavior and underlying properties of the hetero-aggregates as well as the optimization of such properties are not part of the first funding period being applied for here, but part of the second whereby the combined tasks from funding period one and two will allow to reach the aforementioned overall aim of the proposed project.