Formulation of hetero-aggregates in continuously-operated opposed jet fluidized beds

Project Leader :

Prof. Dr.-Ing. Andreas Bück

Friedrich-Alexander-Universität Erlangen-Nürnberg

Dr. rer. nat. Jochen Schmidt

Friedrich-Alexander-Universität Erlangen-Nürnberg

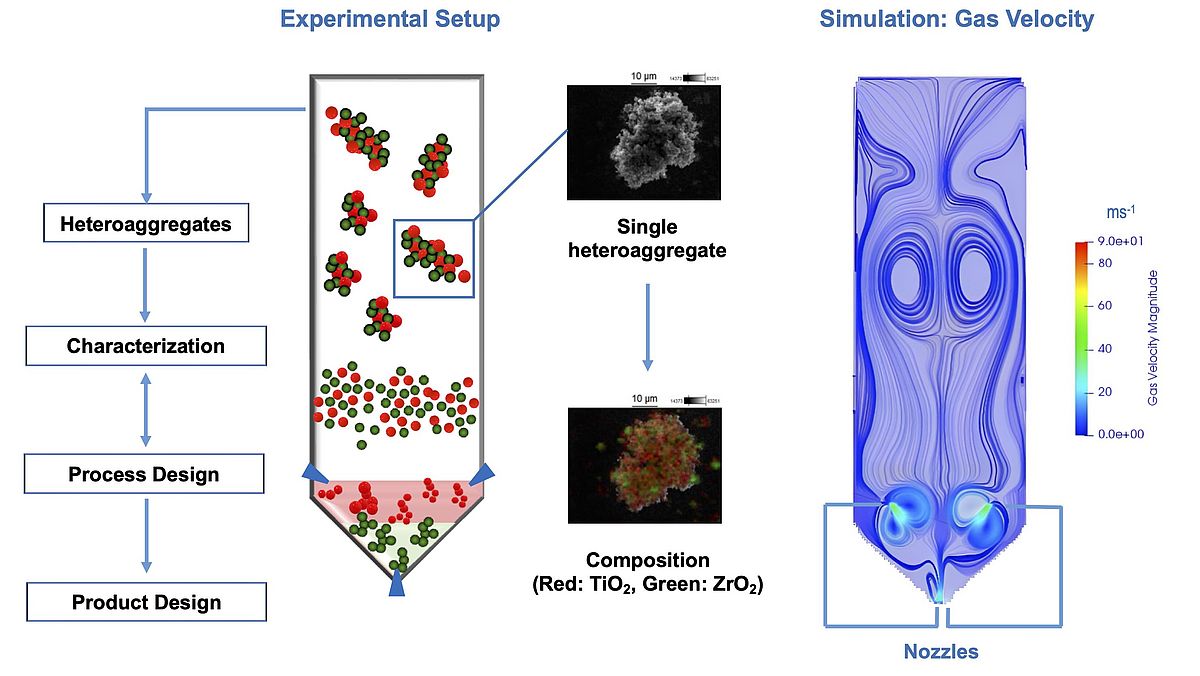

The six-year vision of the project is the establishment of a scalable continuous process for formulation of multinary hetero-aggregates from dry primary particles as an alternative to flame synthesis and aerosol processes. The functionality of the hetero-aggregates will be grounded in the designed composition and distribution of hetero-contacts between constituents achieved by mixing at the primary particle scale (~ 10 nm).

Process modelling is an integral part of the project: Firstly, to establish the process function of the formulation process (in the Rumpfian sense). Secondly, to generate tools for model-based sensor fusion, online measurement, process optimization and control. Comprehensive characterization of hetero-aggregate properties is the link between the experiments and the simulation studies, iteratively providing validation and improvement of process models and experimental design as well as revealing the material functions of hetero-aggregate formulation in opposed jet fluidized beds.

In the first three years, the first funding period, the objectives of the project are:

- Establishment and investigation of a continuous binary hetero-aggregate formulation process in opposed jet fluidized beds;

- Development of a multiphase and multiscale process model for that heteroaggregate formulation process;

- Investigation of systems theoretic properties of the process as a prerequisite for process control and optimization of the formulation process;

- Elucidation of the optical, electronic and photochemical properties of hetero-junctions and hetero-aggregates (bulk behavior); - Linkage of the observed aggregates’ bulk behavior to distinct features of single aggregate structures and band gap characteristics as studied by SEM/EDX;

- Determination of the mechanical properties of single hetero-aggregates by measurements and elucidation of the relationships between aggregate strength, structure and formulation process parameters.

Cooperation is sought throughout the partners of the priority programme, especially in the areas of complementary characterization methods (for example transmission electron and scanning electron microscopy, and electron tomography), aggregate formation process modelling on primary particle scale (for example by discrete element methods), and comparison of process technologies.

The focus of the second funding period is on the transition from binary (over ternary and quaternary) to multinary aggregates by multi-stage operation of the formulation process. New characterization procedures and protocols will be developed to distinguish and quantify the additional opportunities of multi-component hetero-contacts and to unveil the interplay of process parameters and aggregate properties. First-principles models will be extended for the additional tasks of model-based optimization and control, utilizing also data-driven approaches (hybrid/surrogate modelling).