Hetero-aggregation of fine particles in supersonic flow for the tailor-made surface coating

Project Leader :

Prof. Dr.-Ing. Sergiy Antonyuk

Technical University of Kaiserslautern (TUK)

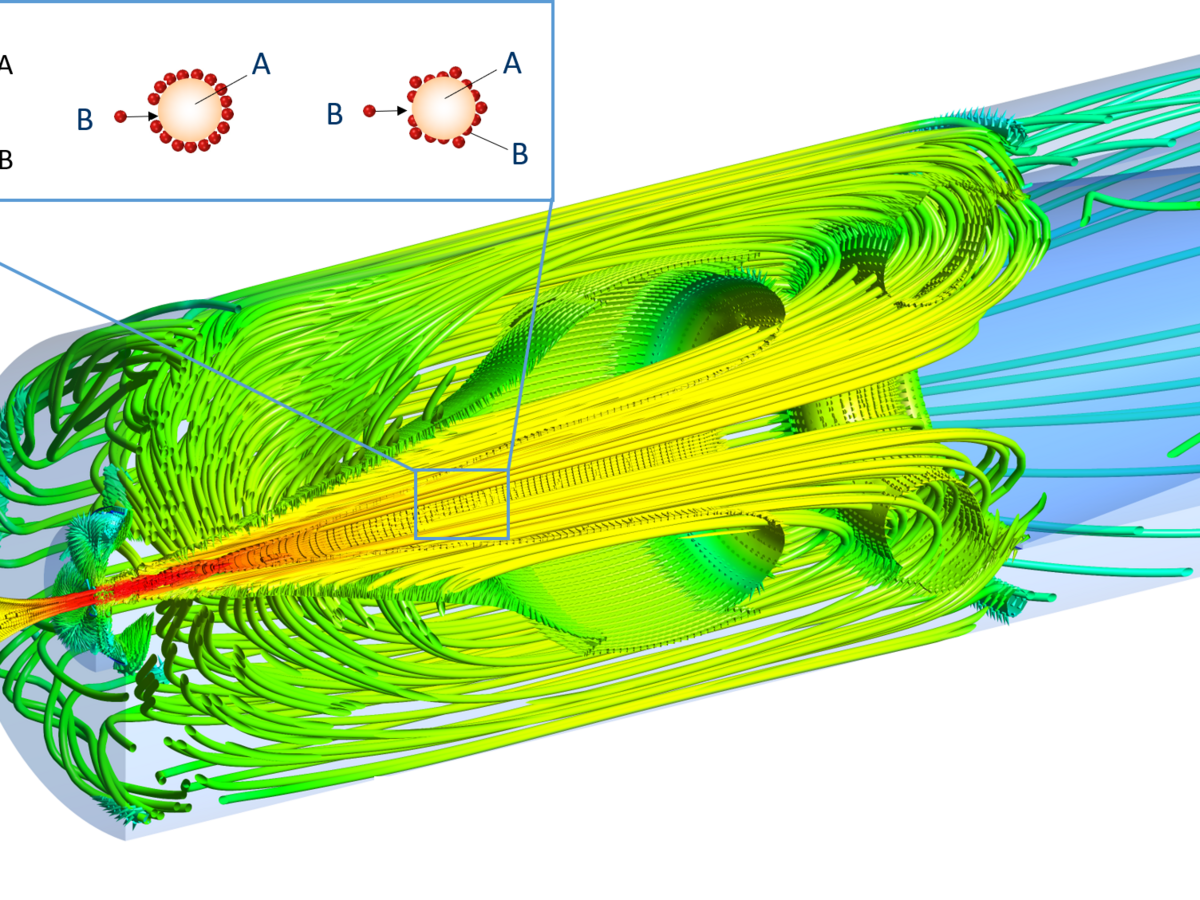

The goal of the planned experimental and theoretical research is the development and description of a hetero-aggregation process of different submicron particles by mixing and desublimation in a supersonic flow for a tailor-made surface coating. For this purpose, hetero-aggregates are generated in the gas phase by a heterogeneous desublimation process. One material is sublimated in the gas phase by a powerful heater before the gas is expanded through a Laval nozzle to a supersonic flow. Due to the strong pressure and temperature reduction, the gas phase is supersaturated and the desublimation on core particles takes place, which are given into a backflow region of the expansion chamber and transported to the region of the highest supersaturation. The mixing behaviour of the components determines the shape and size of the hetero-aggregated particles. The generated hetero-aggregates are characterized according to their size distribution by Scanning Mobility Particle Spectrometer (SMPS) and Scanning Electron Microscopy (SEM). The 3D Light Scattering Sensor will be used for the inline measurement of the particle shape. The complex flow behaviour and aggregate structure are investigated by cross-scale simulations of Computational Fluid Dynamics (CFD) and the Discrete Element Method (DEM). The mechanical deformation and breakage behaviour of hetero-aggregates is studied by nanoindentation and simulated by DEM. The generated hetero-aggregates will be used for the creation of hetero-coatings on wall surfaces by a thermal spraying deposition process. The mechanical properties of the coating layer will be studied by the nanoindentation.