Quantification of the mixing zone and intensification of the mixing process of two nanoparticle producing flames for the design of hetero-contacts

Project Leader :

Prof. Dr.-Ing. habil. Udo Fritsching

Leibniz-Institut für Werkstofforientierte Technologien IWT

Prof. Dr.-Ing. habil. Lutz Mädler

Universität Bremen

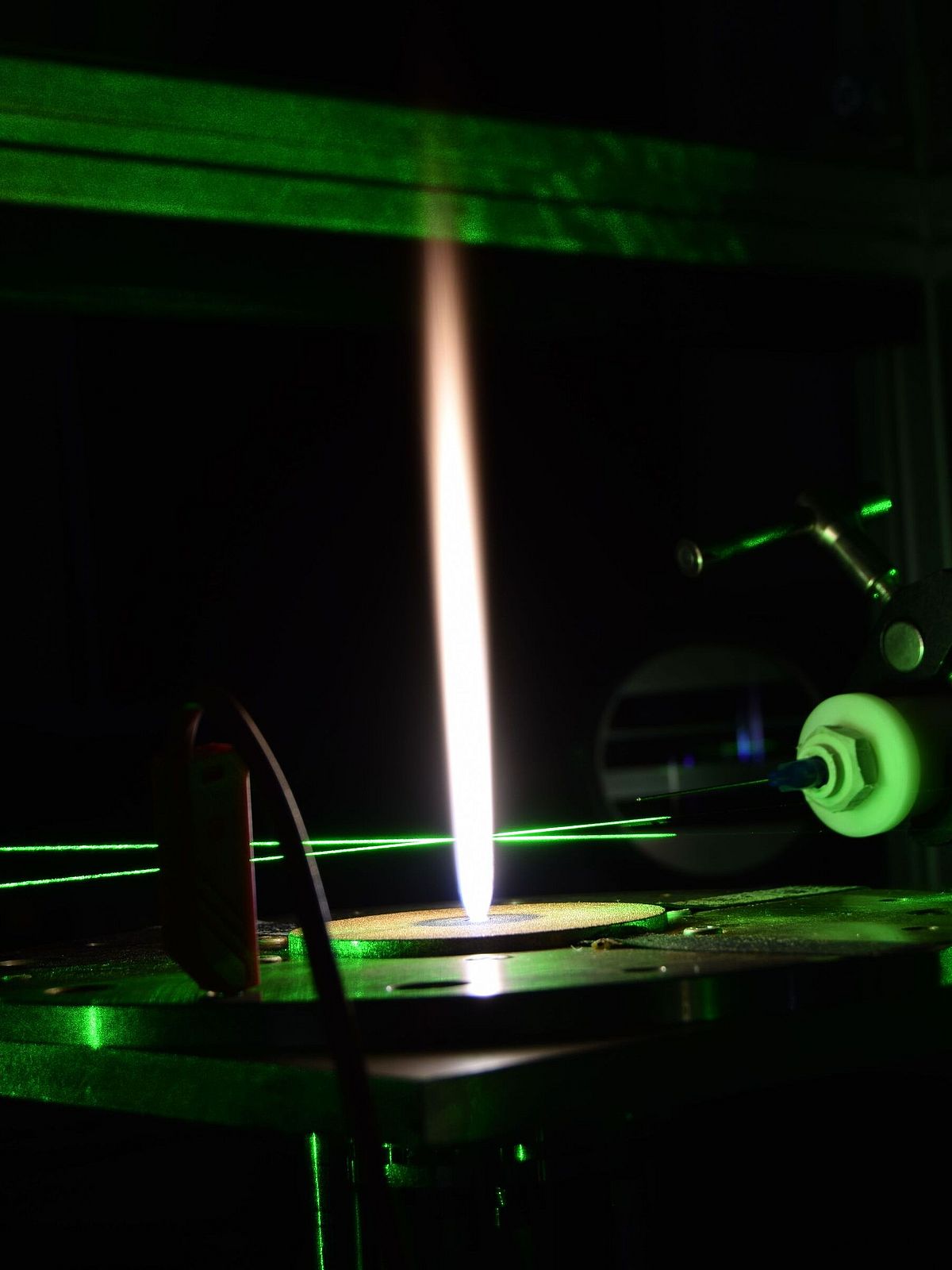

The tailored combination of two nanomaterials with a functional heterocontact is of crucial importance for product properties in various applications in the fields of catalysis, batteries and nanomedicine. By combining two nanoparticle-generating flames by means of double flame spray pyrolysis (DFSP), such a combination is possible to form functional hetero-contacts in aggregates. The product properties can be adjusted by the process parameters such as interaction distance and interaction angle between the two flames.

However, in order to improve product properties in a targeted manner, a detailed understanding of the relevant particle and aggregate formation processes, which take place in a limited area - the mixing zone - is necessary. The aim of this project is to identify and characterize this mixing zone experimentally and by means of CFD simulations in order to subsequently work out the influence of the process parameters interaction distance and interaction angle on the mixing zone.

In order to intensify the mixing process beyond the previous possibilities of the DFSP, two new approaches for process intensification are being investigated: the change of the atomizer gas pressure at the nozzle and an ultrasonic intensification of the mixing zone. By evaluating the mixing state of the particles, we expect to identify fundamental correlations between product properties and the relevant parameters of the mixing process in the mixing zone as well as the process parameters. This would contribute to an improved process understanding as well as the possibility of a targeted adjustment of process parameters and would especially meet the increasing complexity for material combinations of three flames.