Stefan Christian Endres, Lucio Colombi Ciacchi, Lutz Mädler

Journal of Aerosol Science 153 (2021) 105719

doi: https://doi.org/10.1016/j.jaerosci.2020.105719

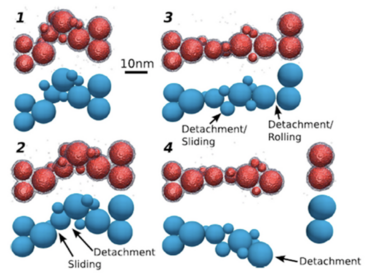

A desire to optimise the production and performance of nanoparticle structured materials has driven the development of increasingly accurate and fundamental models that describe their underlying physical and chemical mechanisms of interaction. In processes where particles form by nucleation and growth, such as aerosol synthesis processes, the primary nanoparticles can form complex assemblies referred to as aggregates, agglomerates and particle films. These materials typically consist of a distribution of primary particles in the nanoscale range (5–50 nm) which form chemically bonded aggregates (typical size range 200–300 nm) during their production. Aggregates in turn form larger structures called agglomerates which are held together by weaker forces arising from electrostatics, van der Waals, solvation or capillary effects. Extended particle assemblies with thicknesses in the order of 1–50 μm over substrate areas of the order of several square centimetre are referred to as particle films. These systems present a particularly challenging modelling problem due to their multiscale nature. Many classical models hold on the mesoscale and macroscale, while on the primary particle level many continuum laws break down and new contact models are required. In these particle-particle contact models, ambient conditions such as humidity have a large effect on the long-range capillary and solvation forces and thus on the final structure of the materials. This publication reviews the work that has been conducted in deducing the discrete physical laws that govern particle-particle contacts as well as their use in practical industrial processes and applications.

/© 2020 The Authors licensed under CC BY 4.0