Charge-induced mixing of particles for the formation of structured materials and their comprehensive characterization

Project Leader:

Dr.-Ing. Christian Lübbert

Friedrich-Alexander-Universität Erlangen-Nürnberg

A bipolar electrospray particle generator (BEPG) will be investigated as source for composition and size defined sub-10nm metal/alloy particles in a two-step process. In the first step cluster ions of metal precursors are formed and mixed in the BEPG. In the second step these salt/metal-organiccompound particles will be reduced to metal particles in a tube furnace. The proposed electrospray/pyrolysis process is an versatile process with respect to generation of inorganic nanoparticles (NPs).

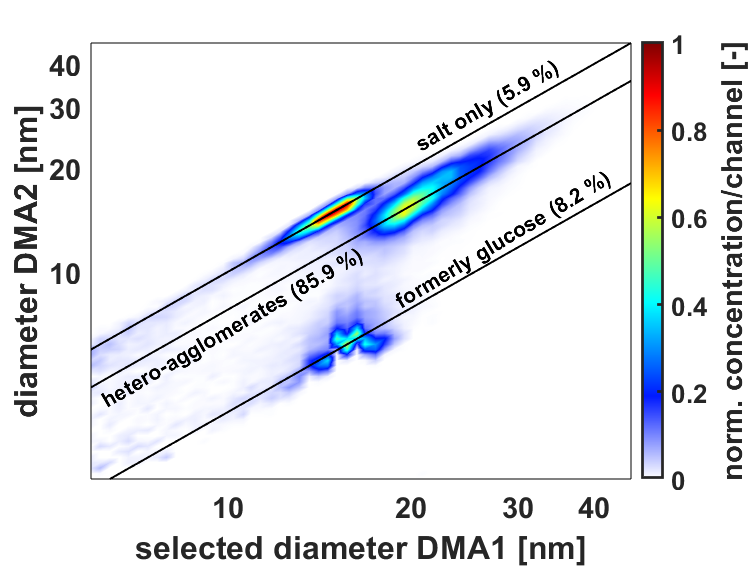

We will focus our investigations on metal/alloy and titania suboxide Magnéli phase synthesis starting with model systems to gain process knowledge and then aim for application in photocatalysis in particular. We will employ electrosprays with very high particle generation frequency (>10^9 s-1) and very small primary drop sizes (< 100 nm). Under such conditions, the products of the two electrospray sources can each be fully characterized by mobility-classified mass spectrometry (DMA-MS). The disperse state (size-/charge-/mass- /mobility-distribution) of each spray and thus the initial conditions of the mixing can be fully characterized by this approach.

Due to efficient particle charge reduction, DMA-MS will work best to characterize very small products of the mixing process. Charge and size distributions of the mixing product at different process stages will be studied online by a tandem-DMA setup before and after thermal treatment. These measurements allow parameter screening of thermal (loss/chemical) conversion process and provide size and charge distribution of the products. The resulting NPs and aggregates will be characterized regarding shape, size, chemical and phase composition using advanced electron microscopy and tomography.

To gain statistical information on disperse particles, an efficient and representative sample harvesting routine by a DMA will be implemented for particle screening in SEM/TEM. An automated correlative workflow enabling highresolution studies on extended particle sets will be developed and will be applied to both metal/alloy NPs and such NPs on titania particle supports. The approach will first be established in 2D to facilitate automated particle screening and high-resolution analysis for reasonable statistics. Insights from the microscopic studies will be correlated with DMA-MS and other averaging particle measurements to derive a deeper understanding of the BEPG process and its process parameters.

In an exploratory way, the microscopic approach will be extended to 3D by combining particle-on-tip preparation routines with scale-bridging 360° tomography. Finally, to link between structural and functional properties of derived metal/titania particle aggregates, photocatalytic measurements will be performed on selected samples and will be related to the occurrence of suboxide Magnéli phase/NP contacts revealed by phase-sensitive analytical TEM mapping.