Shape change history

D04 - Material characterization of the material behavior by measuring the deformation history during forming

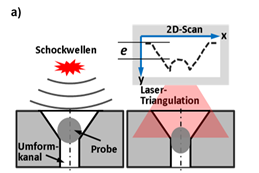

The sub-project is developing a new material characterization method for micro specimens based on incremental electrohydraulic solid forming. Shock waves generated by a wire explosion in a fluid are used for forming, which press the samples step by step through a forming channel in a specially developed extrusion tool. In order to determine material-specific descriptors, the samples are measured between the forming operations using two optical methods. In the integral method, the forming depth e is measured using laser line triangulation and in the spatially resolved measurement of strain fields, the methods of digital speckle photography and digital image correlation are used, for which an optical access was integrated in the extrusion die. With the help of measurement uncertainty considerations for the strain measurement, it could be shown that the achievable uncertainty was sufficient for the measurements, but that new evaluation approaches need to be investigated for a higher lateral resolution. Both characterization methods were used on several materials and provided flow set curves (deformation history), which are suitable as descriptors for further consideration for material characterization.

The new material characterization method for spherical or cylindrical micro specimens represents an approach for future investigations, especially in high throughput. Due to the local detectability of the deformations and the adaptability of the forming channels, it offers the possibility of developing further descriptors for e.g. fracture strength or strain hardening. In addition, production-related characterizations can also be depicted by mapping stage sequences in the forming channels and thus the material behaviour for complex processing cycles can be assessed in advance.

Publications

L. Langstädtler, S. Schnabel, M. Herrmann, C. Schenck, B. Kuhfuss: Short-Term Material Characterization by Electrohydraulic Incremental Extrusion through Micro Channels, Materials 14 - 3 (2021), DOI: 10.3390/ma14030525 (Open Access)

G. Alexe, A. Tausendfreund, D. Stöbener, L. Langstädtler, M. Herrmann, C. Schenck, A. Fischer: Uncertainty and Resolution of Speckle Photography on Micro Samples. Nanomanufacturing and Metrology 3 (2020) 2, 91-104, DOI: 10.1007/s41871-020-00059-2 (Open Access)

D. Stöbener, G. Alexe, L. Langstädtler, M. Herrmann, C. Schenck, A. Fischer: An optical method to determine the strain field on micro samples during electrohydraulic forming. Procedia CIRP 87 (2020), 438-443, DOI: 10.1016/j.procir.2020.02.099

L. Langstädtler, H. Pegel, M. Herrmann, C. Schenck, B. Kuhfuss: Electrohydraulic incremental bulk metal forming, MATEC Web of Conferences 190 (2018) 3001, DOI: 10.1051/matecconf/201819003001 (Open Access)

L. Langstädtler, H. Pegel, M. Herrmann, C. Schenck, D. Stöbener, J.F. Westerkamp, A. Fischer, B. Kuhfuss: Electrohydraulic extrusion of spherical bronze (CuSn6) micro samples, 8th International Conf. on High Speed Forming (2018), DOI: 10.17877/DE290R-18953 (Open Access)

Head

Prof. Dr.-Ing. Bernd Kuhfuß, Prof. Dr.-Ing. habil. Andreas Fischer (BIMAQ)

kuhfussprotect me ?!bimeprotect me ?!.de

Project Management

Dr.-Ing. LasseLangstädtler, Dipl.-Phys. Gabriela Alexe (BIMAQ)

langstaedtlerprotect me ?!bimeprotect me ?!.de