S01 - Process to Generate Rapidly Cooled, Homogenous Samples

An adapted atomization system using a close-coupled atomizer (CCA) has been developed for spray forming of tubular deposit and combined with hot gas atomization (new method for spray compacting) in order to improve the spray-formed materials properties and to expand the existing process window. The principle is available for both Fe and Al base alloys. Laser Doppler anemometers, tow-colour pyrometer and thermal camera were used to record the spray forming process during the experiment.

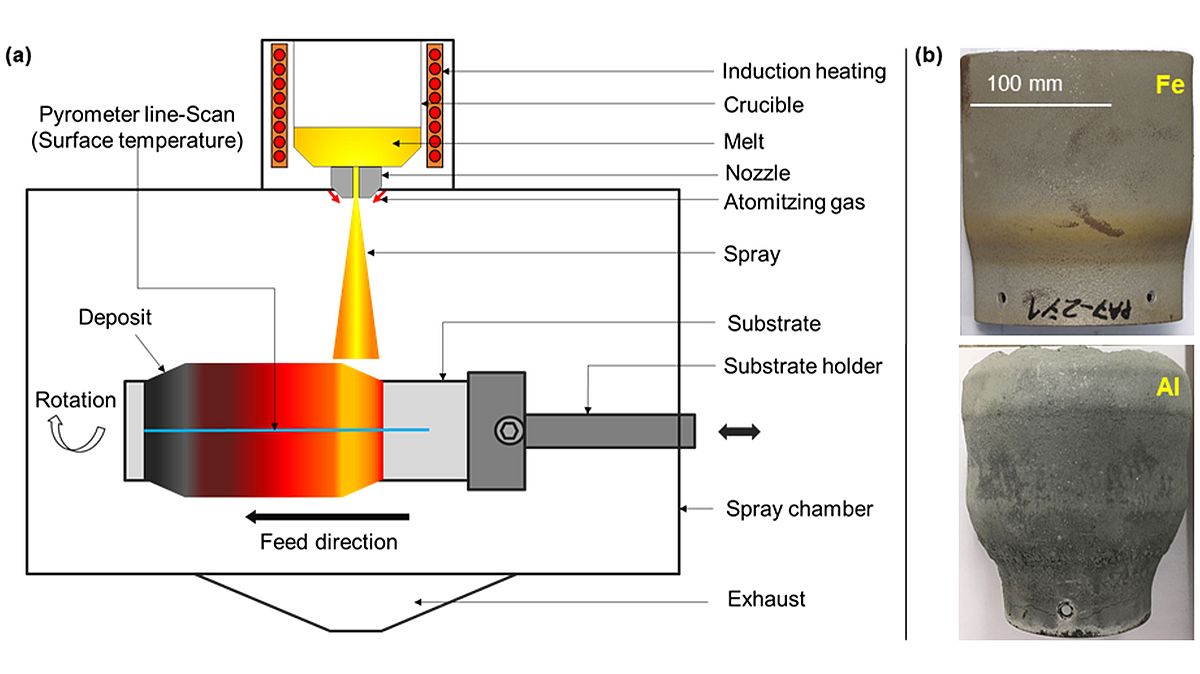

The principle used for the production of rapidly solidified macro samples (Fe and Al base) is shown in Figure 1a. Using CCA, tubular deposit is produced by rotating and axially advancing the substrate tube (diameter 90, 115, 133 mm) with layer thicknesses between 5 to 15 mm. The deposit surface temperatures were measured without contact and the substrate temperatures were also continuously measured using thermocouples. Ring segments were taken from the ring-shaped deposits (Figure 2) and formed by hot rolling (TP S02). Samples were taken from the ring segments to measure the porosity and microstructure. The macro samples were required in the sub-projects (D) to determine process parameters for the database and acted as support points for the predictor function (P01).

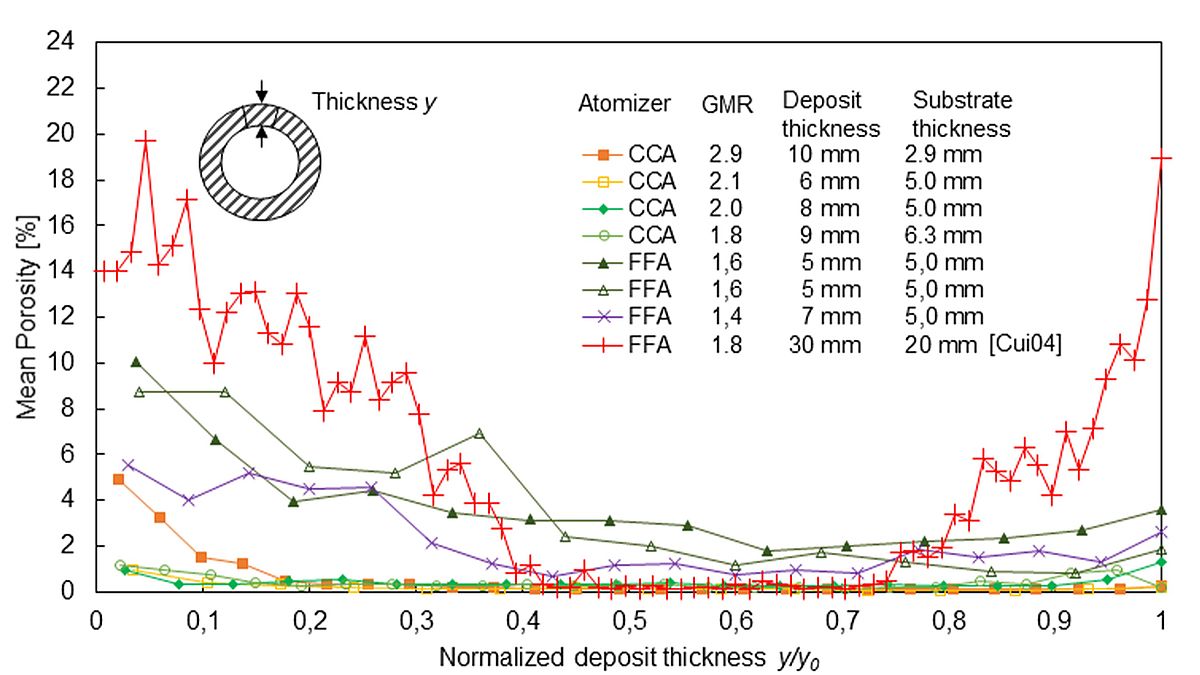

Ring segments were taken from the rapidly solidified tubular deposits in order to determine the porosity on the un-etched section using an image analysis. These results (CCA) were plotted against the relative deposit layer thickness (Figure 3) and compared to the porosity achieved for the same material using a free fall atomizer (FFA). With the CCA, the porous area (porosity greater than 1%) could be significantly reduced both near the substrate and near the surface. Due to the low porosity, the entire sample thickness could be further processed by hot rolling and the material yield increased significantly.

It was assumed that the layer thickness could be increased by a double nozzle system. The double nozzle system has been successfully taken into operation. Both spray cones are stable and spray-formed deposits with a higher thickness could be produced. The interaction between the two gas flows leads to a deflection of the two spray cones by 6 ° each (Figure 4).

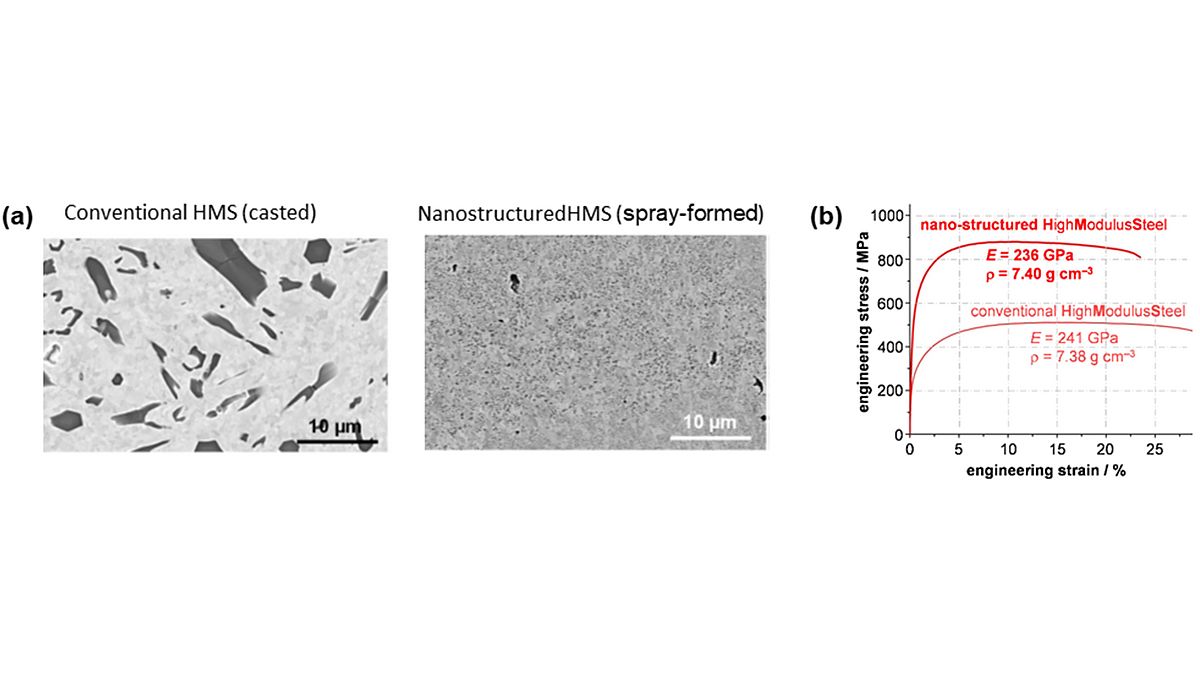

Using the example of a FeTiB alloy, spray-formed and conventional-casted grades were produced for the first time and compared after hot rolling and heat treatment (Figure 5) (S01 and S02). The cast material shows TiB2 precipitates (dark gray) with dimensions up to approx. 10 µm. The spray-formed version has a much finer microstructure with nanometer-sized precipitates. The finely divided precipitates lead to a substantial improvement in the mechanical properties. The tensile strength increases by approx. 60%, whereby the elongation at break decreases only slightly (Figure 5b). In addition, the modulus of elasticity decreases slightly.

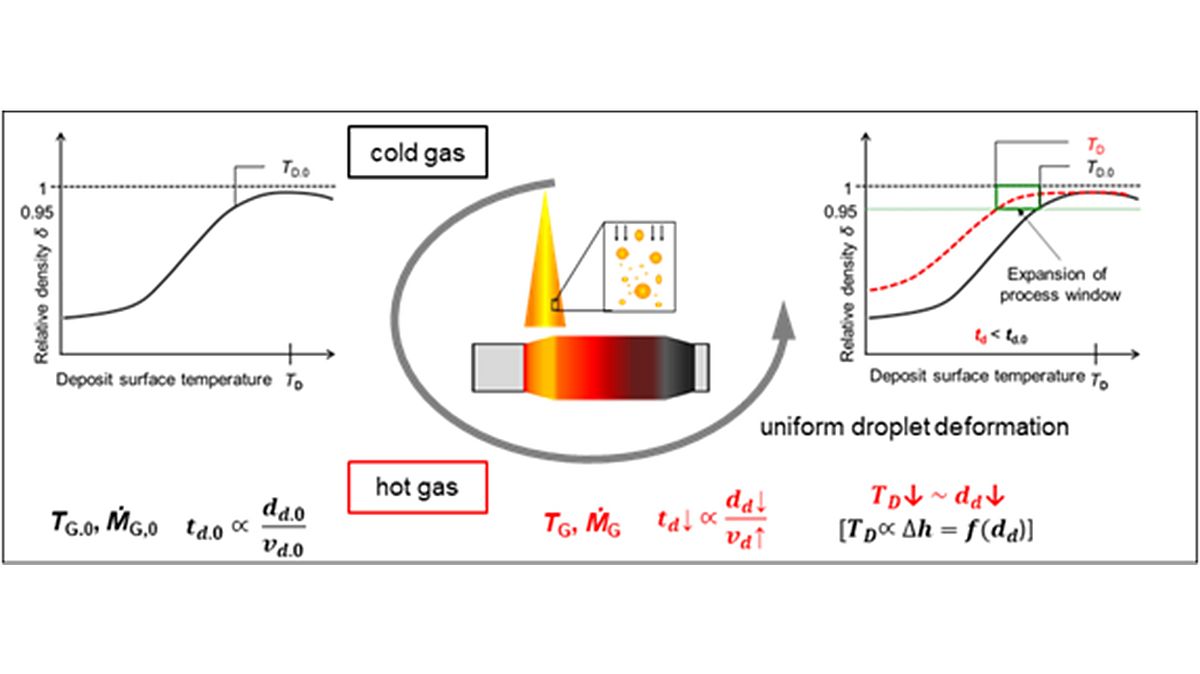

In addition to the deposit surface temperature, the particle impact conditions also play an important role in spray forming. The impact conditions can be massively influenced by increasing the gas temperature (hot gas atomization). For example, if the same atomizing gas pressures are used in the gas nozzle, this leads to a decrease in the gas mass flow rate (gas consumption) when the gas temperature rises and at the same time the average particle size decreases. Based on these assumptions, a hypothesis has been formulated (Figure 6).

The particle velocity was measured using an LDA (Laser-Doppler-Anemometer). It can be seen that particles of the same size accelerate more when the atomizing gas temperature rises, even though the gas mass flow rate decreases (Figure 7b). For spray forming, this means significantly higher impact velocities and which shorten the deformation time (the droplets form when they hit).

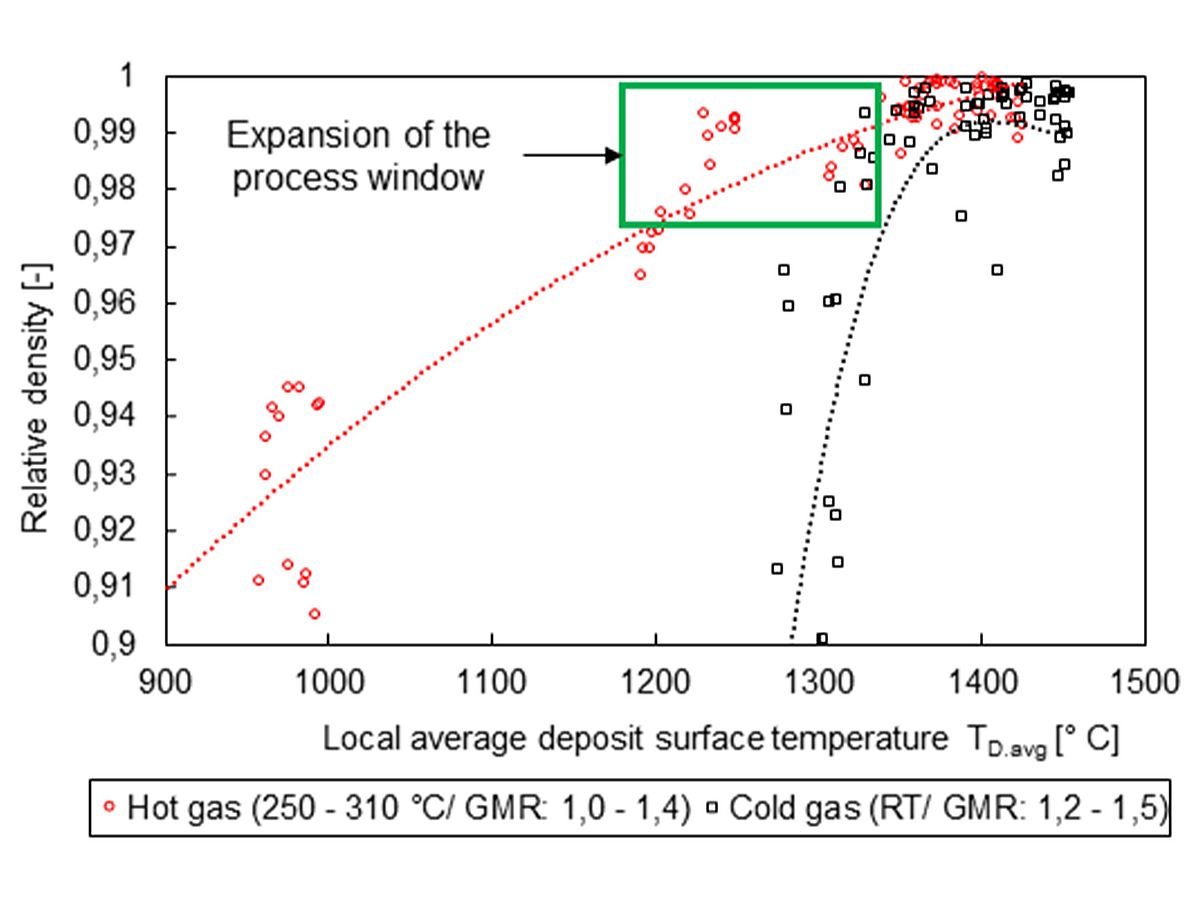

If the relative density of the deposit is plotted against the locally measured deposit surface temperature (Figure 8), a rapidly decreasing relative density is shown when using cold gas. By using hot gas, high relative densities can still be achieved for decreasing deposit surface temperatures.

Publications

H. Springer, C. Baron, F. Mostaghimi, J. Poveleit, L. Mädler, V. Uhlenwinkel: Additive manufacturing of high modulus steels: new possibilities for lightweight design, Additive Manufacturing 2020, https://www.oi.org/10.1016/j.addma.2019.101033 .

S. Hussain, C. Cui, N. Temple, V. Uhlenwinkel, L. Mädler: Porosity and microstructure of steel tubes spray-formed by close-coupled atomizer, Journal of Materials Processing Technology 2020, 276, https://doi.org/10.1016/j.jmatprotec.2019.116407

D. Beckers, N. Ellendt, U. Fritsching, V. Uhlenwinkel: Impact of process flow conditions on particle morphology in metal powder production via gas atomization, Advanced Powder Technology 2019, https://10.1016/j.apt.2019.10.022 .

N. Ciftci, N. Ellendt, G. Coulthard, E. Soares Barreto, L. Mädler, V. Uhlenwinkel: Novel Cooling Rate Correlations in Molten Metal Gas Atomization, Metallurgical and Materials Transactions B, 2019, https://www.doi.org/10.1007/s11663-019-01508-0

H. Springer, C. Baron, A. Szczepaniak, V. Uhlenwinkel, D. Raabe: Stiff, light, strong and ductile: nano-structured High Modulus Steel, Sci Rep 2017, 7, 2757 https://www.doi.org/10.1038/s41598-017-02861-3

Head

Dr.-Ing. Volker Uhlenwinkel

uhlenwinkelprotect me ?!iwt.uni-bremenprotect me ?!.de

Project Management

Shohag Hussain

s.hussainprotect me ?!iwt.uni-bremenprotect me ?!.de

![[Translate to English:] Zur Startseite des SFB Farbige Zustände](/fileadmin/user_upload/sites/sfb1232/Logos_und_Bilder/SFB1232-quer.png)