U: Primary Shaping and Micro Structure Development

Head

Prof. Dr.-Ing. habil.

Lutz Mädler

Universität Bremen

Fachbereich Produktionstechnik

Fachgebiet Mechanische Verfahrenstechnik

Badgasteiner Straße 3, 28359 Bremen

Processes and methods for the synthesis of micro samples were chosen by focusing on their microstructure. It is supposed to enable as many options as possible for following mechanical, thermal and thermos-mechanical treatments to realize a high outcome of samples within a short period of time while keeping high flexibility regarding the desired variety of alloy. The CRC envisages working on two synthesis techniques which differ fundamentally in their conceptual approach. While one of the methods is based on melt drop generation, the other one uses a solid and a laser beam to locally fuse defined layers of material. In high- throughput synthesis, both methods produce a variety of sample geometries with different microstructures for treatments. Those happen to be evaluated regarding their suitability for the method “Farbige Zustände”. This results in subprojects, which work closely linked to the process principles of the production of macro samples in project area S (S01 (Process to generate rapidly cooled, homogenous samples ) and S02 (Correlative study towards experimental validation of the high throughput methodology)):

- U01: Generation of spherical microscopic samples with single droplet solidification

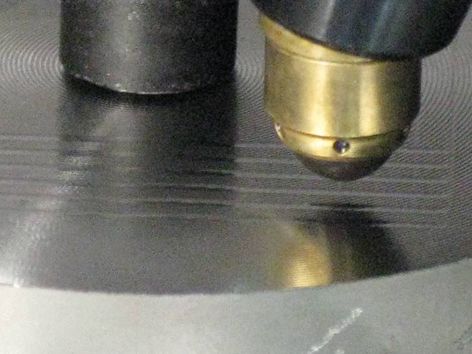

- U02: Laser deep alloying for the realization of finely graded alloys

Similar considerations are made for selecting the processes of treatment. Those may be divided in thermal, thermomechanical, and mechanical treatment. The use of inductive heat treatment and laser heat treatment is provided; both methods differ in their dynamic. To mechanically treat the samples those are either deep rolled or micro samples shot peened at high velocities. Again, those methods differ in their dynamic. Other than that a thermomechanical solidification of samples is planned. Resulting projects are:

![[Translate to English:] Zur Startseite des SFB Farbige Zustände](/fileadmin/user_upload/sites/sfb1232/Logos_und_Bilder/SFB1232-quer.png)