Flow sensor based air management in fruit and vegetable storage (COOL)

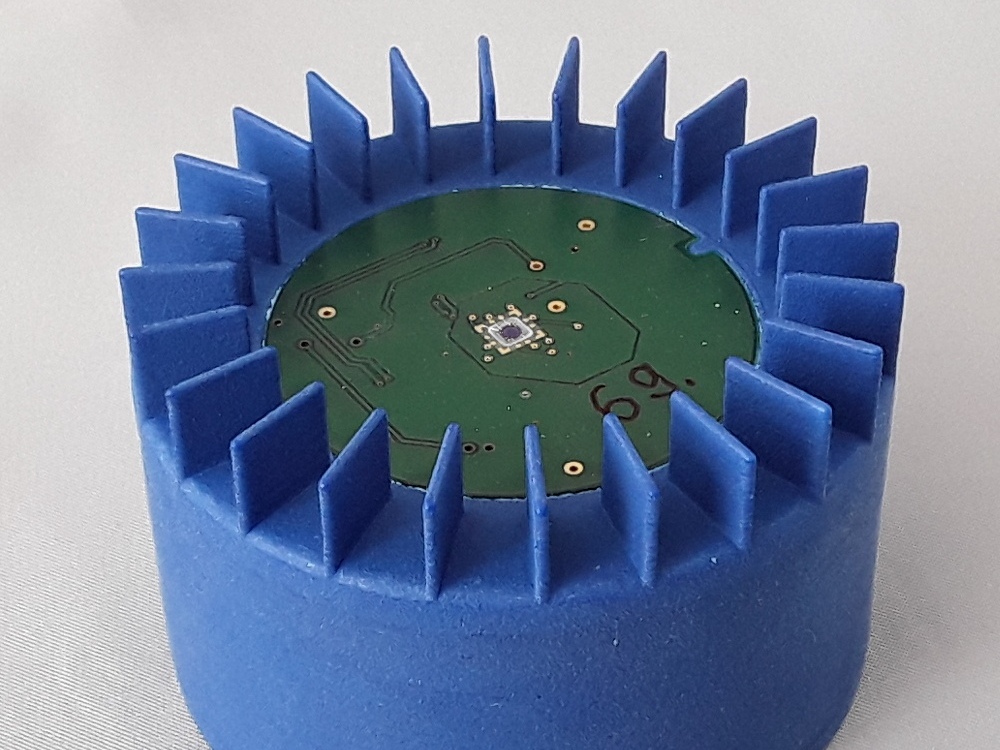

In the research project, COOL researchers pursue a novel approach to optimize cooling ventilation. Their aim is to allow energy savings of over 20% and to improve the quality preservation of the stock. Saving energy and reducing losses ist the aim of the project.

Fruits and vegetables are stored for up to eight months in large cold storage rooms in batches of several hundred tons. Up to 40% of the electrical energy required for the operation of these spaces is consumed by the coolers circulating the air. The high energy consumption of about 80 kWh per ton product and storage season as well as the quality and mass losses in the stored goods are key cost factors for machine-cooled fruit and vegetable storage.

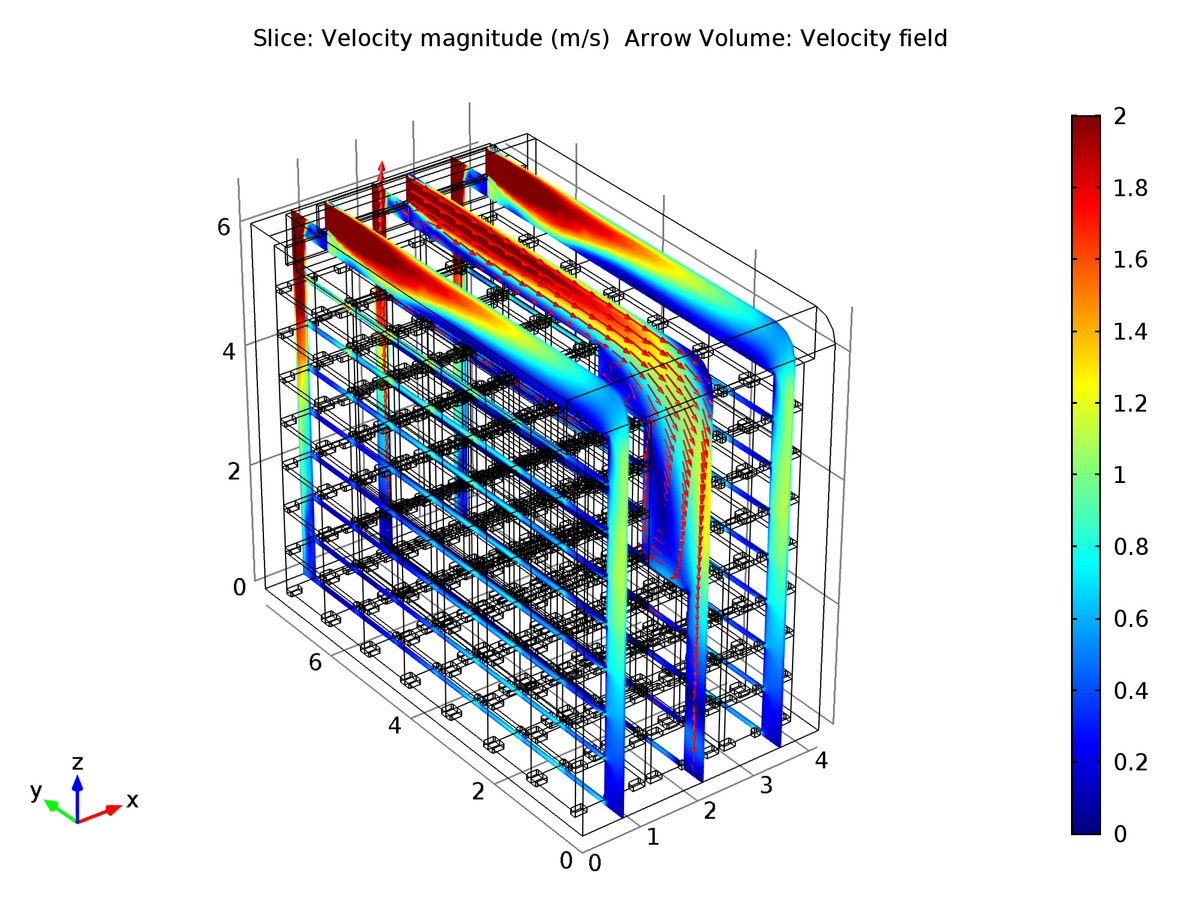

To preserve the quality of fruits and vegetables as best as possible way during storage, it is necessary that cool air flows around the products in the bulk bins evenly and sufficiently. For this, the air flow in the gaps between the crates and within the crates must be as evenly as possible.

Normally refrigeration systems are controlled based on only few temperature sensors in the room. Thus, there is no guarantee that the air is flowing around the products throughout the room uniformly and at a sufficient rate.

Contact IMSAS:

Dr.-Ing. Reiner Jedermann

IMSAS, NW1, Room O 2130

Tel: +49 421 218 62603

E-mail: contact

Project Coordinator:

Dr. Ulrike Praeger

Leibniz Institut für Agrartechnik Potsdam-Bornim e.V.

Tel. +49 0331 5699-917

E-mail: upraegerprotect me ?!atb-potsdamprotect me ?!.de

The Project COOL is being financed by the German Bundesministerium für Wirtschaft und Energie from July 2015 to October 2017.