Facilities

Photolithography

- Contact-Lithography

- Laser-Lithography

- 3D-Lithography

Thermal Processing

- Oxidation

- Diffusion

- Annealing

- Parylene Coating

Deposition

- Low Pressure Chemical Vapour Deposition

- Low pressure chemical vapor deposition (LPCVD)

- Plasma Enhanced Chemical Vapor Deposition (PECVD)

- Sputtering

- Evaporation

Etching

- Wet Etching

- Reactive Ion Etching (RIE)

- Deep Reactive Ion Etching (DRIE) / Advanced Silicon Etching (ASE)

- Ion Milling Etching

- Plasma etching (PE)

Electro Plating

Waferbonding

- Silicon Fusion Bonding (SFB)

- Anodic Bonding

- Eutectic Bonding

- Solder Bonding

- Glass-Frit Bonding

Chemisch-Mechanisches Polieren (CMP)

Assembly and Packaging Technology

IMSAS has a great variety of specialised equipment to enable assembly and packaging technology at the ende of the MEMS production:

- Waferdicing

- Chipbonding

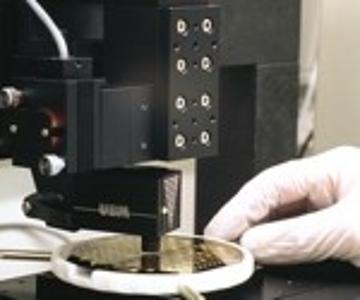

- Wirebonding

- (PCB) Processing

Test and Characterizing

For fabrication as well as for testing and characterization of MEMS (Micorelectromechanical Systems) devices IMSAS has a multitude of measuring instruments and stations:

- Film-Thickness Measurement Tools

- Step Height Prober

- Surface Profiler

- 3D Measurement System

- Gauge for film stress

- 4-Point Resistivity Prober

- Scanning Electron Microscope (SEM)

- X-Ray Fluorescence Spectrometer

- Pressure Measuring Station

- Flow Measuring Station

- Gas Measuring Station

- Climatic Exposure Test Cabinet

- Impedance spectroskopy

Design und Simulation

Numerous design and simulation tools enable IMSAS to create and optimize MEMS designs in-house:

- CoventorWare®

- LabVIEW®

- MATLAB®

- COMSOL Multiphysics®

Cleanrooms

IMSAS uses a variety of facilities for research, development and production of state-of-the-art microsystems. Two large class ISO 6 cleanrooms with an overall area of 900 m² for front-end and back-end processing of 100 mm and 150 mm wafers are available, offering the complete range of standard MEMS processes: