3D Materials Analytics

3D X-ray microscopy & 3D X-ray microtomography

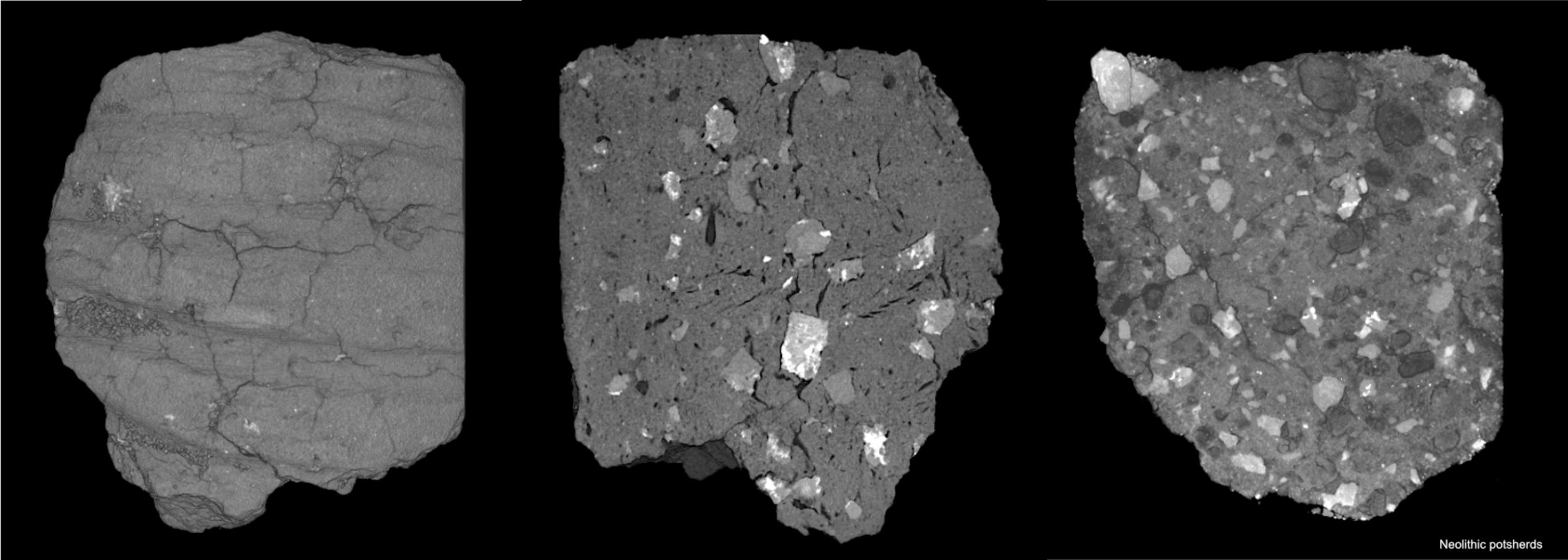

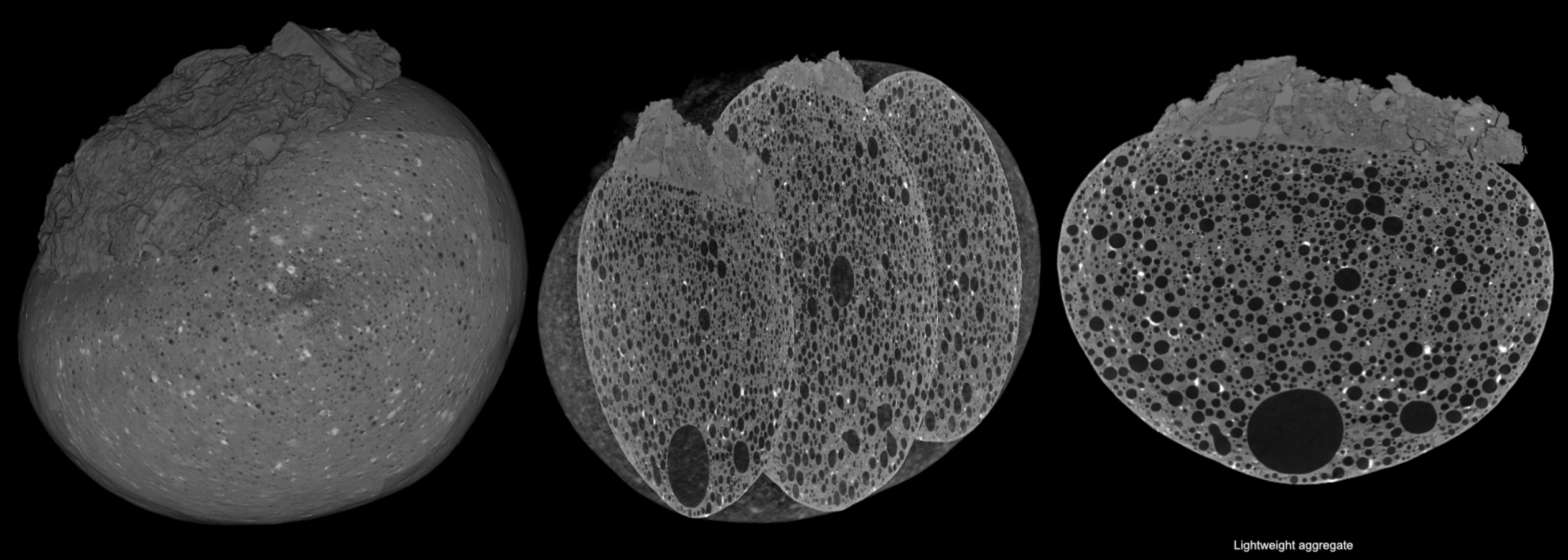

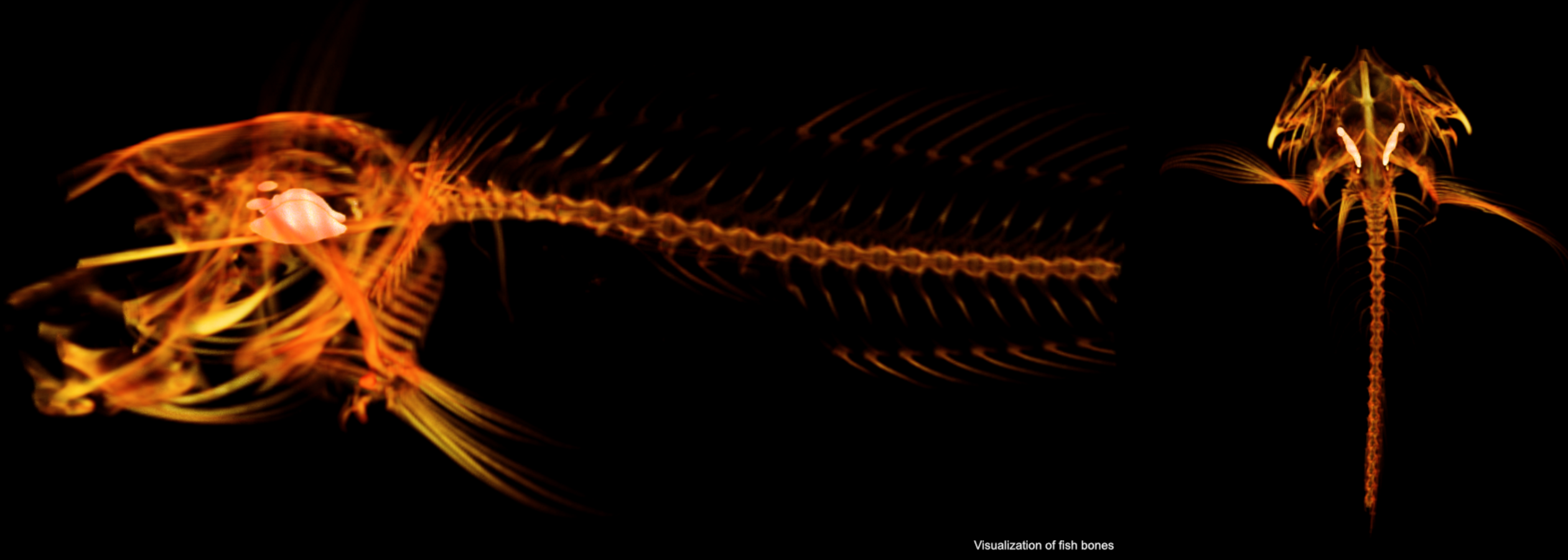

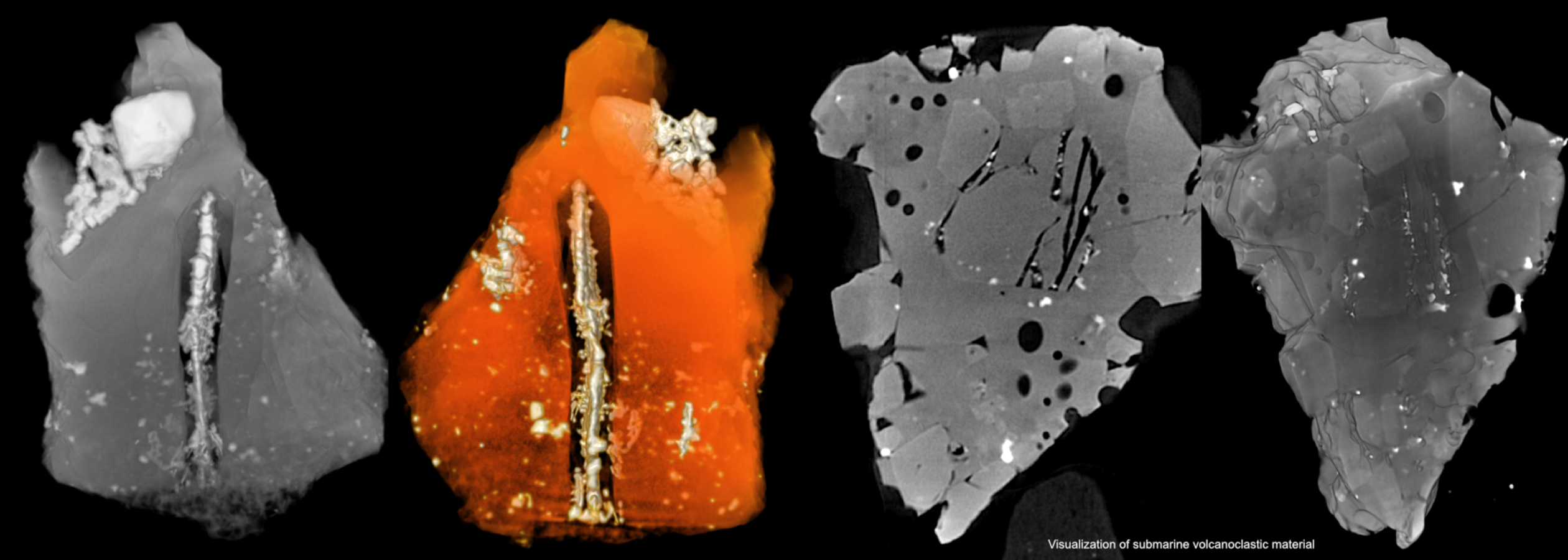

Our methods are based on the detection and subsequent localization of the degree of attenuation of the incident X-rays in the sample. The attenuation of X-rays by matter depends on both the chemical elements it consists of as well as the material density. The information about the varied X-ray absorption is encoded as grey values in the black-and-white images. The volume reconstruction facilitates, e. g., visualization of fabric compounds as 3D models, or preparation of virtual thin sections in any desired direction.

What kind of result do I get?

The result of our non-destructive 3D X-ray analysis is the reconstructed spatial distribution of X-ray attenuation within the object, in the form of a digital image stack or as an image volume. Each image consists of voxels (volumetric pixels) and allows quantitative analyses of volume and surface properties, or size distributions of different fabric compounds, etc. In addition, the transmission images can be supplied. Any analysis of the tomography data is possible in the context of scientific cooperation.

mehrPrincipal Investigator

Prof. Dr.-Ing. Axel S. Herrmann

Application Scientist

Dr. Wolf-Achim Kahl

Lab Manager 3D X-Ray Microscope

MAPEX Center for Materials and Processes

University of Bremen

Am Fallturm 1, D-28359 Bremen

Phone: +49 421 218 64581

Fax: +49 421 218 64599

Email: wakahlprotect me ?!uni-bremenprotect me ?!.de

www.hmi.uni-bremen.de/Kahl/kahl_home.html

Our key instruments

Zeiss Xradia 520 Versa

3D X-ray microscope

- max. 10W, 160 kV

- resolution 0.3 to 25 µm per voxel

- Sample size ca. <1-50 mm

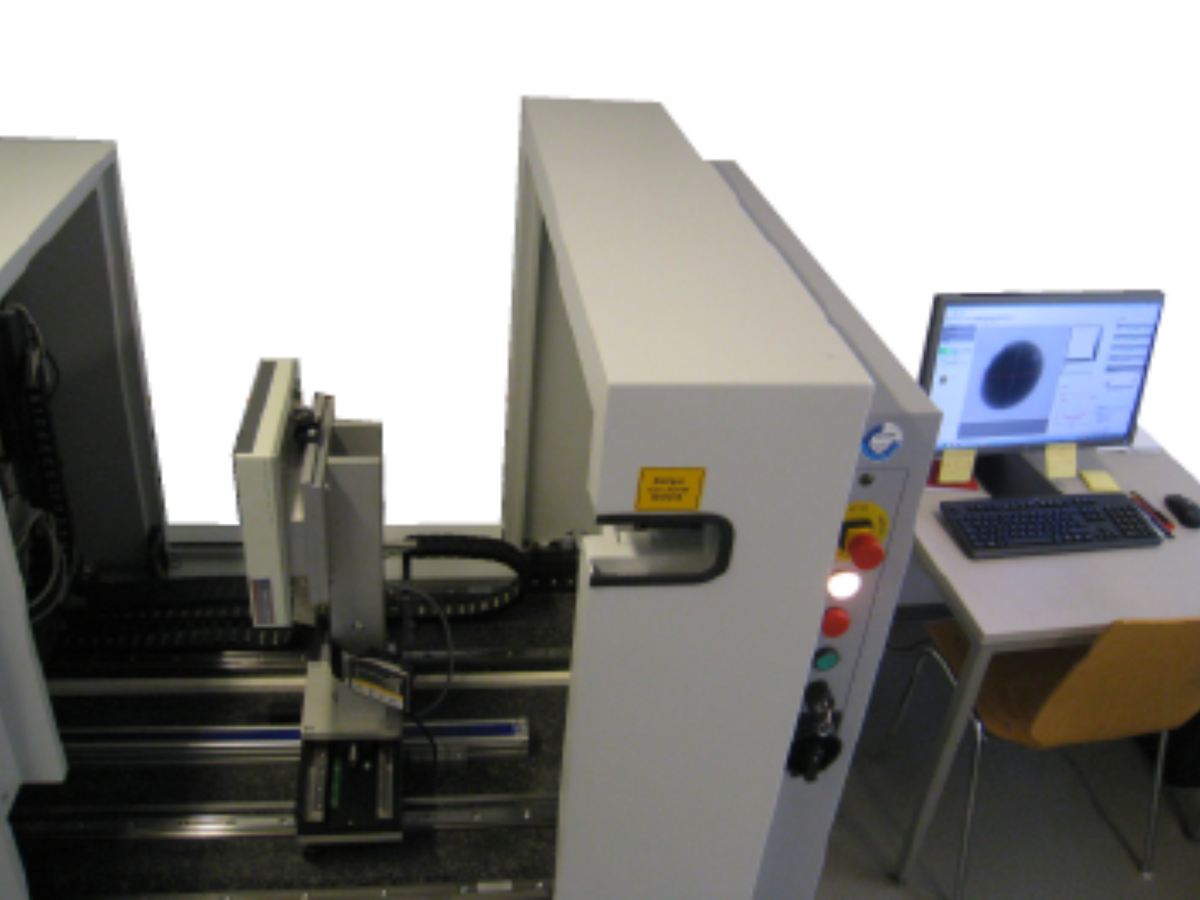

ProCon CT-ALPHA

Micro X-ray computed tomograph

- max. 50W, 190 kV

- resolution 1-35 µm per voxel

- Sample size 1-100 mm

Phoenix-xray v|tome|x m

Micro X-ray computed tomograph

- 2 tubes: 320 W, 240 kV/15 W, 180 kV

- resolution (2 tubes): >3 µm / <1 µm

- Sample size: 1-60 mm

More available instruments

Current instrumentation belonging to MAPEX-CF can be found in the Instrument Database of the MAPEX Center for Materials and Processes.