Non-destructive 3D materials analytics

The 3D X-ray microscopy and microtomography technique, like medical tomography, employs X-rays to inspect the three dimensional distribution of matter inside the object of investigation.

The term “micro” indicates that the resolution achieved is in or below the μm-range. The method is based on the detection and subsequent localisation of the degree of attenuation of the incident X-rays in the sample. The attenuation of X-rays by matter depends on both the chemical elements it consists of as well as the material density. As a result of the reconstruction procedure after the scan, each image consists of voxels (volumetric pixels) and has a certain thickness depending on the detector resolution. Thus, a stack of images contains true volumetric information.

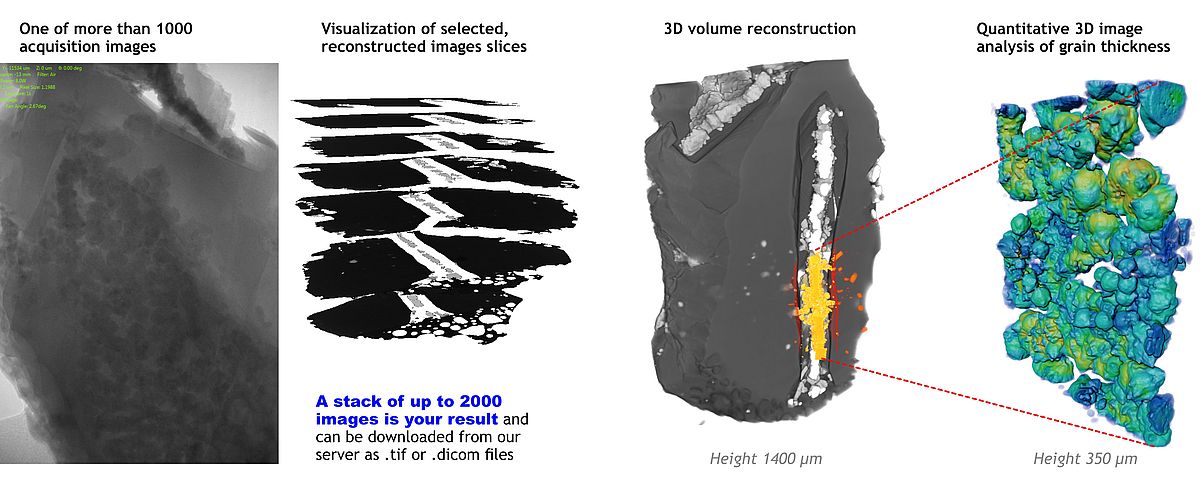

Stack of grayscale images encoding X-ray absorption

The result is the reconstructed spatial distribution of X-ray attenuation within the object, in the form of a digital image stack or as image volume, which can be transferred from our lab servers. A storage medium will not be provided. In addition, the transmission images can be supplied.

Advanced 3D quantitative image analyses

Any further data treatment, visualization or quantitative image analysis is not part of our service. However, the XRM lab personnel will be happy to discuss the possibilities of a scientific cooperation. In this context advanced 3D quantitative image analyses for joint publication is possible.

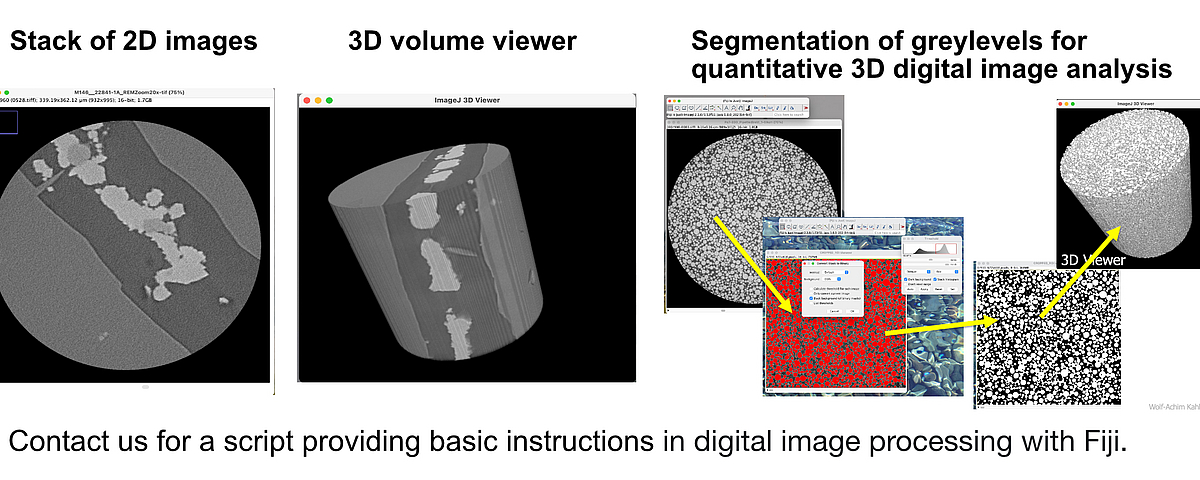

How to explore your 3D volume data

3D volume data represents the reconstructed spatial distribution of X-ray attenuation within the object, in the form of a digital image volume. As an exchange format, the 3D data can be downloaded from the lab server as a stack of 2D images.

There are many image processing software packages with a variety of capabilities for rendering and quantitative 3D image analysis. Among those, the free software Fiji facilitates scientific image processing and analysis on all major platforms.

Feel free to contact us (Wolf-Achim Kahl) for a script providing some basic instructions of first steps in digital image processing with Fiji.

Voxel size and resolution - What does it mean?

In general, voxel size is the actual size of a 3D pixel in your actual volume dataset. This can be changed during image processing. Nominal resolution is the smallest voxel size of a scanner's reconstructed image corresponding to the beam path of the scan.

The final image resolution cannot be better than the voxel size. However, because of other factors such as spot size of the X-ray source, image reconstruction or partial volume effects of particles smaller than the voxel size, resolution is reduced and information is smeared out over neighbouring voxels. Resolution can be 2-5 times of the voxel size.

Detectability refers to the smallest object that still can be seen in an image, depending on high contrast width between object and background. For instance, a gold particle (high attenuation) on a graphite surface (low attenuation) sized even smaller than the resolution of the scanner will still be detectable, while a glass particle (medium attenuation) will not.

Sample size versus voxel size

Very high magnification scans that aim at voxel sizes below 0.5 μm require the usage of the 20x X-ray objective. This item in turn demands very long beamtimes. Therefore, we recommend the preparation of samples smaller than 1 mm to keep beam times reasonably short. For instance, a detector binning of 1000 voxels aiming at 0.25 μm resolution will cover a field of view of only 250 microns. All other parts of the sample will not be imaged, but lower transmission severely.

![[Translate to English:] Workflow of sample analysis](/fileadmin/_processed_/9/4/csm_Workflow-sample-analysis_5x2_01_d1733fd0b4.jpg)