...a non-destructive exploration of the density distribution

ZEISS Xradia 520 Versa

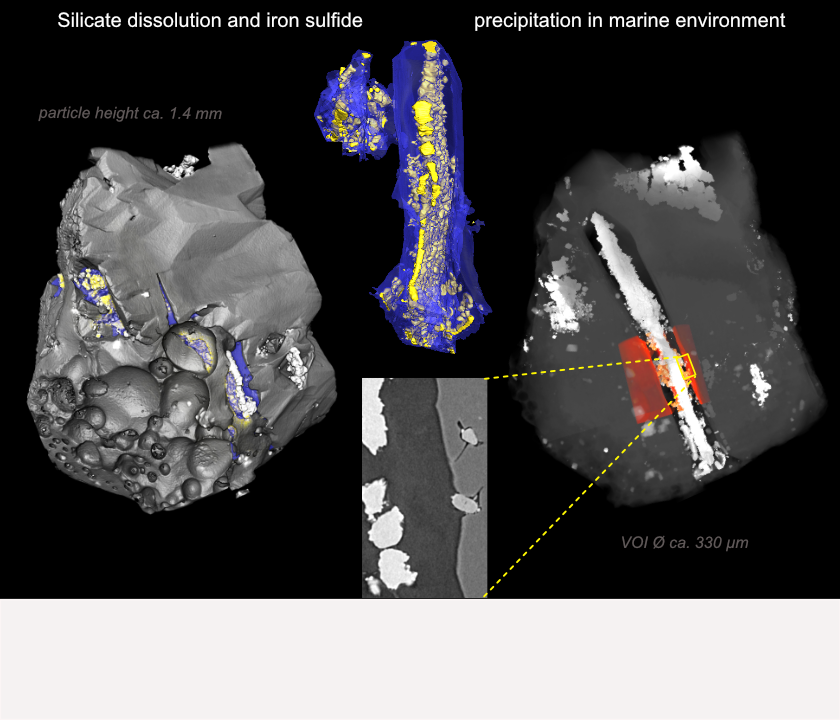

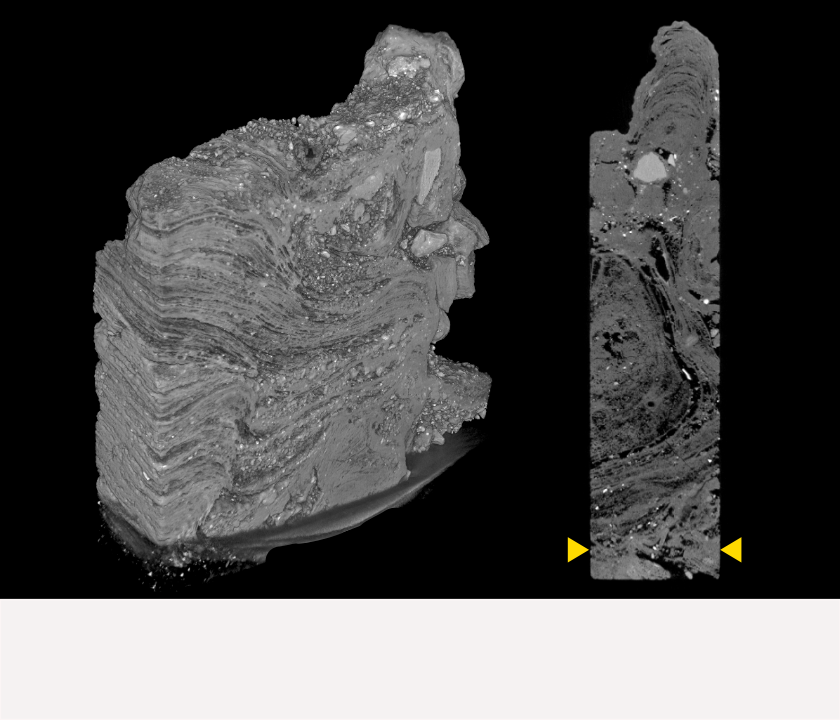

Enhanced weathering in the seabed

Rapid olivine dissolution and iron sulfide precipitation

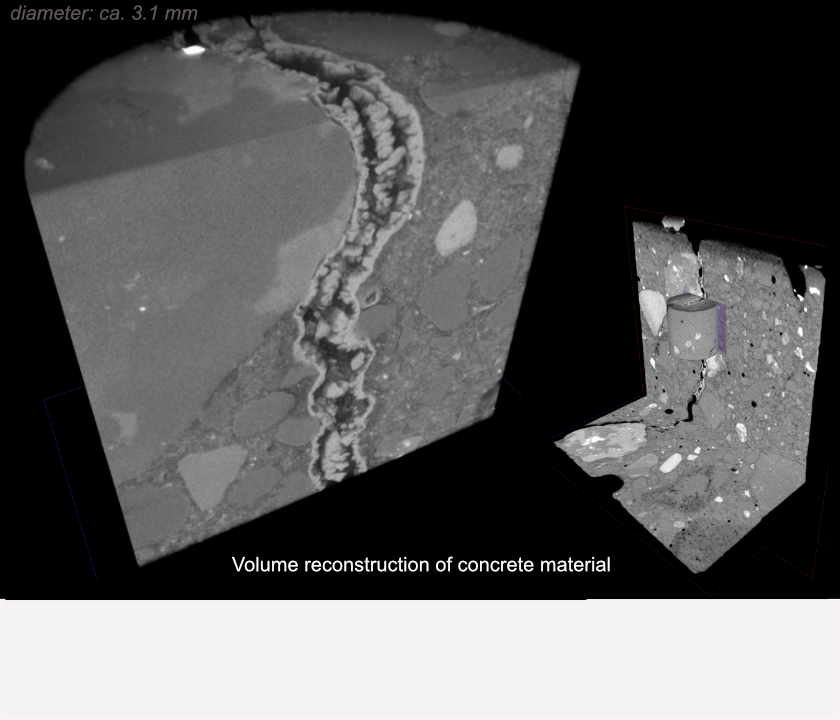

Visualization of concrete material

Mineralization in cracks

Microbial colonization along cracks

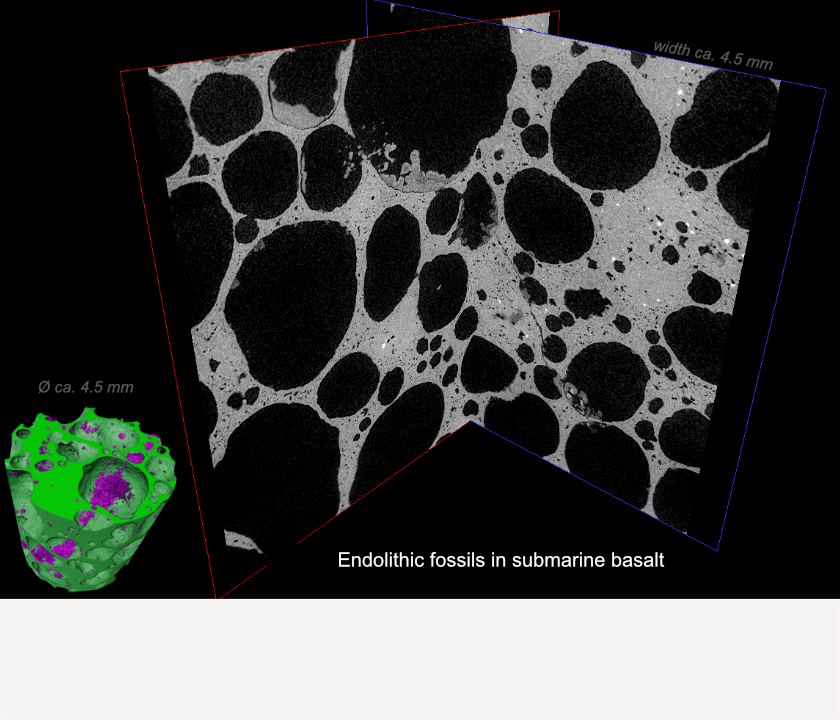

Endolithic fossils in submarine basalts

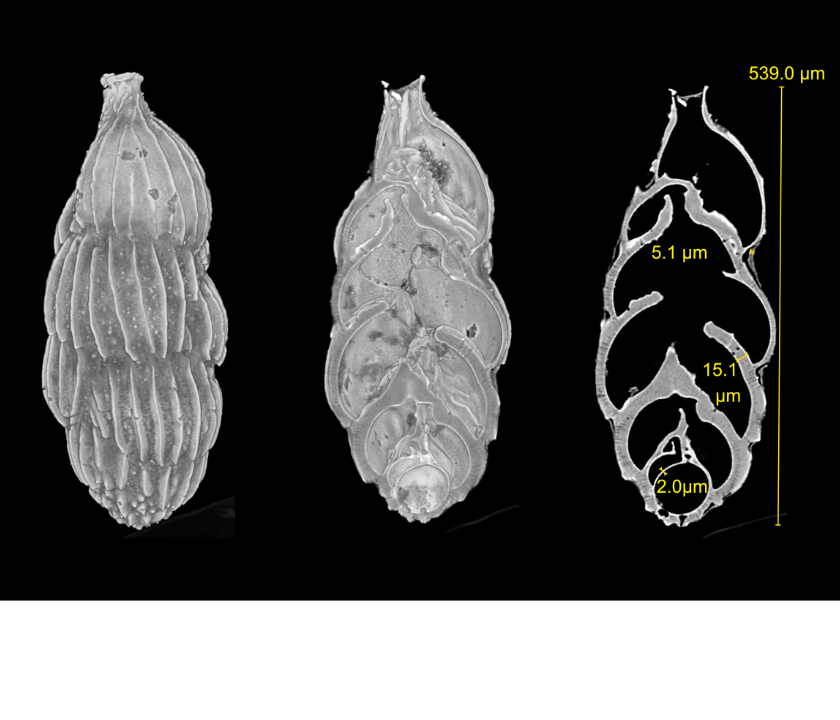

Foraminifera

Height 539 µm

Natural silica sinter

Width ca. 3 mm

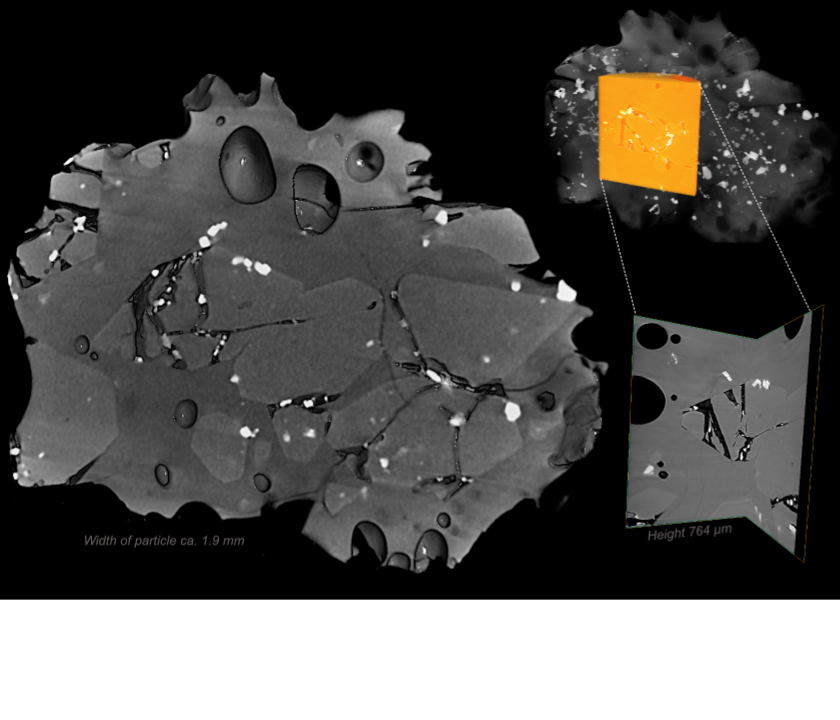

Submarine volcanoclastic material

Orange subvolume depicts localization of a high-resolution scan

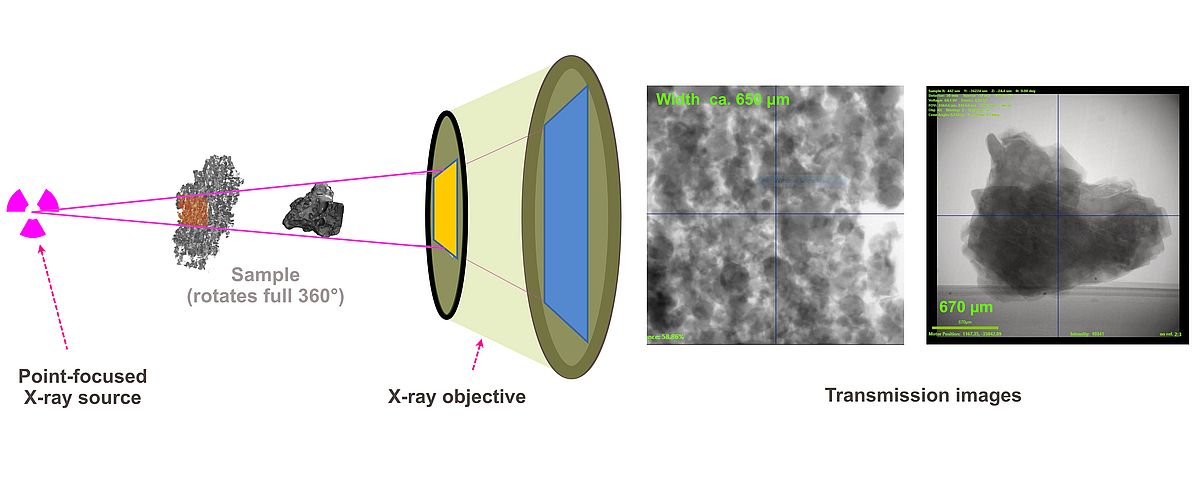

The scanner

Our ZEISS Xradia 520 Versa is equipped with a 160 kV micro focus X-ray source with maximum 10 W. Due to a unique setup of scintillator and 16-bit CCD 2024 x 2024 pixel camera, magnification is achieved by a two-stage technique including a microscope objective system. This enables a beam path through the sample with very little divergence, which is allows large working distance at high resolutions. The standard imaging mode of the XRM can be modified to offer several additional imaging techniques.

The method

The method is based on the detection and localisation of the degree of attenuation of the incident X-rays in the sample. The attenuation of X-rays by matter depends on both the chemical elements it consists of as well as the material density. The information about the varied X-ray absorption in encoded as grey values in a stack of black-and-white images. Each image consists of voxels (volumetric pixels) and contains true volumetric information.

Sample types and preparation

X-ray microscopy can characterize all materials that are transparent for X-rays, e.g bio-materials, polymers, fiber textile materials, ceramics, semiconductors, rocks, or metals. The sample surface does not have to be prepared in advance. In our lab we analyze biological samples (e.g , grashopper's legs, cotton), fiber composite materials, hot spring silica sinters, metal powders, and many more.

moreSample size and - geometry

In general, samples of any shape can be investigated. Although a cylindrical shape is most favorable for X-ray microscopy, also thin or flat pieces can be imaged with a scan mode optimized for a samples with a high aspect ratio. Sample size may range from a few millimeter to several centimeters. Most important for a successful scan is a sufficient transmission of the object for X-rays. It is also possible to scan selected sectors of a sample.

moreAdvanced imaging techniques

Phase contrast for low-z tomography

The distinct X-ray microscope beam optic allows to move both source and detector far from the sample while still achieving high magnification. This constellation engages the propagation phase contrast mode, which by detecting Fresnel diffraction fringes allows to image the interfaces of different patches or grains consisting of the same material.

moreDual-energy scans separate similar z

On rare occasions, element content and density of materials match unfortunate to be indistinguishable by a single-energy scan. In these cases, a distinct segmentation can be attained by a software-guided process combining the outcome of a low-energy scan (where X-ray absorption is dominated by photoelectric effect) and a high-energy scan (here X-ray absorption is mostly determined by Compton scattering).

Diffraction contrast tomography (DCT)

Laboratory DCT is performed by adding an aperture and beamstop to the X-ray path in order to acquire diffraction patterns of crystalline materials. In combination with a standard absorption tomography, 3D crystallographic information such as grain size, shape and orientation can be retrieved. Sample should be roughly 1-2 mm in size. For LAB-DCT observations, the XRM personnel will modify the XRM beam setup, and will accompany the measurements.

Deben mechanical test stage

The XRM lab is equipped with a Deben mechanical testing stage, which allows X-ray microsopy surveillance of in-situ experiments in one of the three modes: Compression, tension, and indentation. For mechanical in-situ observations, the XRM personnel will modify the XRM sample setup to host the testing stage, and will accompany the mechanical testing experiments.

moreWhat resolution can I expect?

Relevant for the attainable resolution in a XRM beam geometry is actually the sample's overall transmissivity for X-rays, which for a given piece is mostly linked to the sample size. In general, very small samples (1-3 mm) can be characterised with high resolution (0.3 - 0.7 µm per voxel), and larger samples (10-50 mm) with lower resolution (3-25 µm per voxel).

moreWhat kind of result do I get?

The result is the reconstructed spatial distribution of X-ray attenuation within the object, in the form of a digital image stack or as image volume, which can be downloaded from the lab server. A storage medium will not be provided. In addition, the transmission images can be supplied. An analysis of the tomography data is possible in the context of a scientific cooperation.

moreContact

Contact person for technical information

Dr. Wolf-Achim Kahl

Analytical service

Requests for analyse services are welcome for both academic and non-commercial customers. Please contact

Prof. Dr.-Ing. Lucio Colombi Ciacchi (e-mail: colombiprotect me ?!uni-bremenprotect me ?!.de) or

Dr. Wolf-Achim Kahl (e-mail: wakahlprotect me ?!uni-bremenprotect me ?!.de).

For usage regulations of X-ray microscope follow the link:

more