Inorganic mineral foam

Inorganic mineral foam

Residual materials of industries like steel working or incineration plant are decoupled at temperatures above 1000 °C, cooled down and deposited as slag. So far, attempts for heat recovery from molten slag suffered from low thermal conductivity of 2W/mK. A possible solution is a further processing of the molten slag forming product where conventional production route is energy intensive, namely foam glass. The composites of slag and waste glass are similar. Furthermore foam glass is an attractive insulation product with the disadvantage of high primary energy demand in production (24.5 GJ/t).

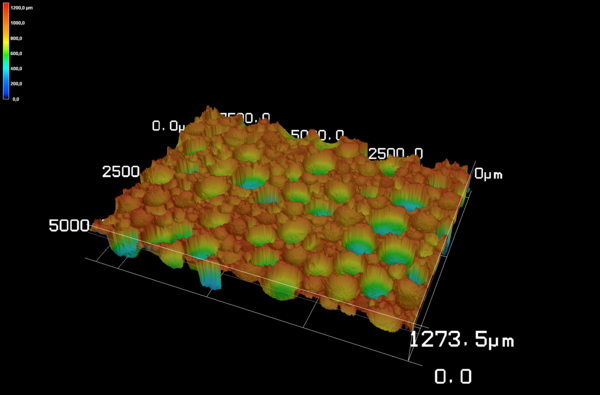

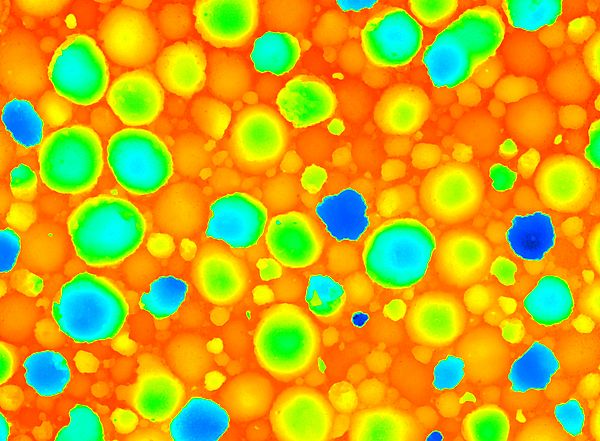

Stereoscopic view inorganic mineral foam

Inorganic mineral foam

To reduce the energy demand it is to use molten slag, mix it with waste glass and a thermal decomposing mineral. The energy is provided by the molten residue material. A homogeneous pore size distribution is depending first on the material itself and second on the blending of molten slag. Thus the actual scientific issue focus on the systematic investigation of the mixture and the thermal conditions. The technical aim is the production of a foam slag glass with low thermal conductivity and high compressive strength.

Contact:

Dr. Michael Baune

Raum UFT 2180

Tel. 0421- 218 - 63385