Suman Pokhrel, Muhammad Ali Martuza, Jan Derk Groeneveld, Marco Schowalter, Andreas Rosenauer, Johannes Birkenstock, Lutz Mädler

Powder Technology 465 (2025): 121318

https://doi.org/10.1016/j.powtec.2025.121318

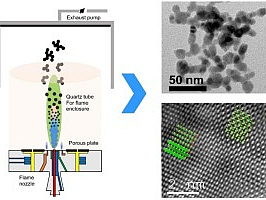

The synthesis of Cu₁.₈S, ZnS, and Cu₁.₈S-ZnS composite nanoparticles is achieved via reactive spray combustion, wherein rapid vaporization of thiophene initiates micro-explosions that promote high-temperature vapor-phase reactions under reducing conditions. High-resolution transmission electron microscopy (HRTEM) and X-ray diffraction (XRD) analyses reveal that the synthesized nanoparticles consist of agglomerated spherical primary crystallites, with average sizes of 12.2 nm for Cu₁.₈S, 10 nm for ZnS, and 10.8 nm for the Cu₁.₈S-ZnS composite. Elemental analysis via energy-dispersive X-ray spectroscopy (EDX) coupled with scanning transmission electron microscopy (STEM) confirms homogeneous spatial distribution of Cu and S in Cu₁.₈S, elevated surface oxygen content in ZnS attributed to physisorption, and substantial Cu incorporation into the ZnS lattice within the Cu₁.₈S-ZnS composite system. Structural analysis indicates that the contrast features observed in Cu₁.₈S, ZnS, and Cu-Zn mixed sulfides are consistent with their respective crystallographic symmetries, where sulfur atoms adopt well-ordered lattice positions, while copper exhibits partial site occupancy and electron density disorder attributed to the comparable ionic radii of Cu2+ and Zn2+ ions. This study underscores the efficacy of oxygen-deficient, reducing flame environments in facilitating the synthesis of binary and mixed-metal sulfide nanomaterials, enabling the formation of metastable phases providing a scalable, cost-effective route for producing advanced functional materials with broad application potential.