Elektrode-based DEP filtration

Another way to increase the throughput of DEP separators is to scale electrode-based structures. In contrast to insulator-based DEP filtration, in this case an electrode structure at the bottom of the channel with closely spaced electrodes generates the inhomogeneous electric field. Microfluidic electrode arrays from clean rooms are typically used, but these are limited in size and costly to manufacture. Our concept is based on specially manufactured, yet inexpensive printed circuit boards (PCBs). This allows the effective flow cross-section to be significantly increased in width, if not in height, and throughputs of up to 600 mL/h have been achieved. At the same time, the positive properties of microfluidic DEP structures are retained, so that highly selective separations are still possible.

One focus of our current research is on the separation of electrode materials from lithium-ion batteries and the recovery of gold from mining residues (tailings), which has not been possible with conventional methods to date, or only at an uneconomical cost.

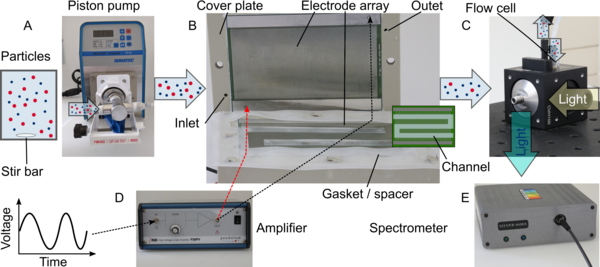

Experimental setup based on a printed circuit board. The particles are suspended in water and pumped into the separation device (B) using a piston pump (A). Two printed circuit boards, on which the electrode arrays are located, form the separation chamber. The electrodes are connected to an amplifier that supplies a sinusoidal voltage to operate the device (D). The suspension emerging from the channel flows into a flow cell (C) that is coupled to a light source. The resulting fluorescence signal is recorded by a spectrometer (E) connected to a computer.

Workflow of dielectrophoretic particle chromatography (DPC). (A) Top view of the microfluidic device (sketch). (B) The microfluidic separation column (side view, height h = 80 μm and electrode width/spacing d1 = d2 = 100 μm) is continuously flushed with a carrier fluid. The device is used for two different types of experiments. (I) The crossover frequency of the particles is determined using field-flow fractionation (FFF) at a fixed frequency f by comparing the elution profiles with and without applied voltage (V0) (C). The particle properties obtained were used as input parameters for a full-scale simulation model implemented in COMSOL Multiphysics to find suitable process parameters (D). (II) Finally, the set of process parameters is used as a starting point for experiments to achieve chromatographic separation using frequency-modulated (f = f(t)) DPC (E).

Relevant publications in this field

Giesler, J. M. (2024). Process Development of Electrode-Based Dielectrophoretic Separators. Dissertation, Universität Bremen (Germany).

https://doi.org/10.26092/elib/2759

Giesler, J., Weirauch, L., Thöming, J., & Baune, M. (2024). Compensation of capacitive currents in high-throughput dielectrophoretic separators. Scientific Reports, 14(1), 16491.

https://doi.org/10.1038/s41598-024-67030-9

Giesler, J., Weirauch, L., Rother, A., Thoming, J., Pesch, G. R., & Baune, M. (2023). Sorting lithium-ion battery electrode materials using dielectrophoresis. ACS omega, 8(29), 26635-26643.

https://doi.org/10.1021/acsomega.3c04057

Giesler, J., Weirauch, L., Thöming, J., Pesch, G. R., & Baune, M. (2024). Dielectrophoretic Particle Chromatography: From Batch Processing to Semi-Continuous High-Throughput Separation. Powders, 3(1), 54-64.

Contact

Dr.-Ing. Laura Weirauch

Room UFT 2110

Tel. 0421- 218 - 63496

lweirauchprotect me ?!uni-bremenprotect me ?!.de