Isolator-based DEP filtration

Most conventional DEP applications are based on microfluidic technology, i.e., on very small scales of channels and electrodes, and are operated at low flow rates. Scale-ups are difficult because the field gradient decreases very rapidly with distance from the generating electrode array. With dielectrophoretic filtration, we are researching a way to circumvent this inherent limitation. Here, the field gradient required for DEP is generated by the disturbance of the field at insulating structures. The insulating structures can be, for example, porous ceramics, glass bead fillings, or polymer fabrics, which then function as (electrically) switchable filters. In this case, the field gradient is decoupled from the throughput, which enables operation on a preparative or even industrial scale. If the filter structures are large enough so that no particles are separated by size exclusion, the trapped particles can be recovered after the field is switched off.

Current research topics include the material-selective separation of microparticles, e.g., electrode materials from lithium-ion batteries, and advancing into the nanoplastics range while maintaining high throughputs.

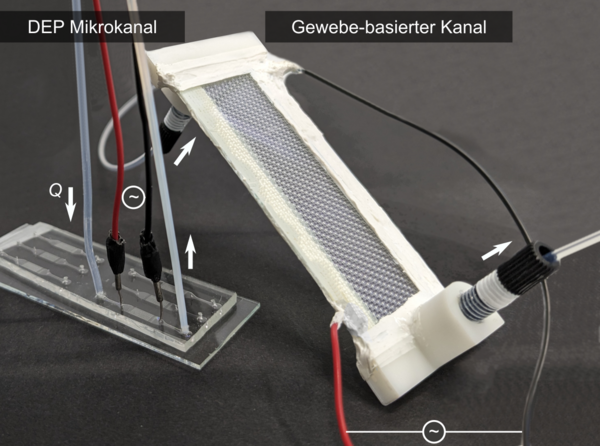

Development of the DEP channel size over the course of the project. Left: DEP microchannel for investigating the fundamental relationships. Particles with a diameter of less than 5 µm are reversibly trapped in the gradient maxima at the field disruptors (columns) and can then be released again through remobilization. Right: DEP filter in which the microscopic columns have been replaced by a regularly woven plastic mesh. The throughput in this prototype has already been increased by a factor of 1000.

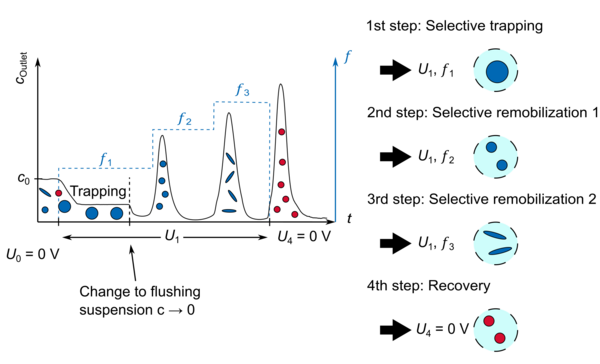

Schematic diagram of multidimensional separation according to size, shape, and material in a DEP filter. In several steps, all particles except for one type are first retained in the filter and then selectively released again. Separation and remobilization are controlled by the frequency f of the electric field and are specific to the properties of the particles. The graph on the left shows which particles are detected at the channel outlet during the course of the experiment.

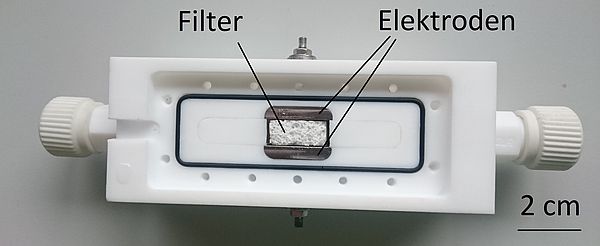

Open DEP filter cell as an example of DEP filtration in porous media. The filter ceramic can be seen in the middle between the two electrodes.

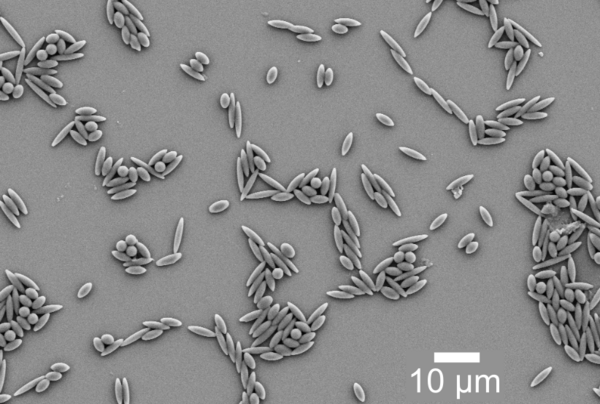

Fluorescent polystyrene microparticles transformed in the stretching process for investigating the influence of shape.

Relevant publications in this field

Kepper, M. (2025). Tailoring of filtration matrix design in dielectrophoretic filtration: towards selective separation for industrial tasks. Dissertation, Universität Bremen (Germany).

https://doi.org/10.26092/elib/3617

Weirauch, L., Giesler, J., Pesch, G. R., Baune, M., & Thöming, J. (2024). Sorting microparticle mixtures by multiple properties in a single dielectrophoretic filter. Results in Engineering, 23, 102641.

https://doi.org/10.1016/j.rineng.2024.102641

Kepper, M., Rother, A., Thöming, J., & Pesch, G. R. (2024). Polarisability-dependent separation of lithium iron phosphate (LFP) and graphite in dielectrophoretic filtration. Results in Engineering, 21, 101854.

https://doi.org/10.1016/j.rineng.2024.101854

Weirauch, L. (2023). Multidimensional sorting of microparticles in electrically switchable dielectrophoretic filters. Dissertation, Universität Bremen (Germany).

https://doi.org/10.26092/elib/2692

Pesch, G. R., & Du, F. (2021). A review of dielectrophoretic separation and classification of non‐biological particles. Electrophoresis, 42(1-2), 134-152.

Contact

Dr.-Ing. Laura Weirauch

Room UFT 2110

Tel. 0421- 218 - 63496

lweirauchprotect me ?!uni-bremenprotect me ?!.de