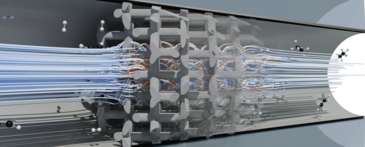

Catalytic reactors play an important role in the transition to a more sustainable society. They are crucial to store excess electrical energy by converting green Hydrogen into gaseous or liquid carriers like methane or methanol (Power-to-X, PtX). Here we present how Computational Fluid Dynamics (CFD) can contribute to an optimization of PtX processes by investigating the heat transport through catalyst support structures and optimizing its geometry based on bio-inspired shapes. Also, we present first results of Magnetic Resonance Imaging (MRI) experiments of a gas-phase reaction to compare them with reactive CFD simulations. The results illustrate the complexity of multi-scale reactions as well as its potential to revolutionize the research on reactor systems.

Kevin Kuhlmann is a PhD student at the Chemical Process Engineering group at the Center for Environmental Research and Sustainable Technology, University of Bremen. After his bachelor studies in the field of biomimetics and a research internship at Columbia University (New York City, USA), he finished his master’s degree in production engineering in 2019 focusing on computational fluid dynamics. Within his PhD project he tries to gain deeper understanding of the processes within catalytic reactors, which are key for the production of chemicals as well as the storage of energy in liquid and gaseous carriers.